Analytical tools like Inductively Coupled Plasma (ICP) Spectroscopy and Total Acid Number (TAN) can quantitatively determine the depletion of additives. However, these techniques cannot predict the additive effectiveness in forming stable tribofilms under boundary lubrication that can sustain lower friction and wear. A measurement tool that can work at the same pace as that of ICP and TAN, with an excellent precision in friction and wear repeatability will add more robustness in their oil analysis. Conventional tribo-test methods are used to investigate friction and wear behaviour of additives, according to international test standards like ASTM, DIN, IP and ISO. However, a single test can last up to 60 minutes, and this is an obstacle for most oil analysis labs where hundreds of tests per day need to be performed.

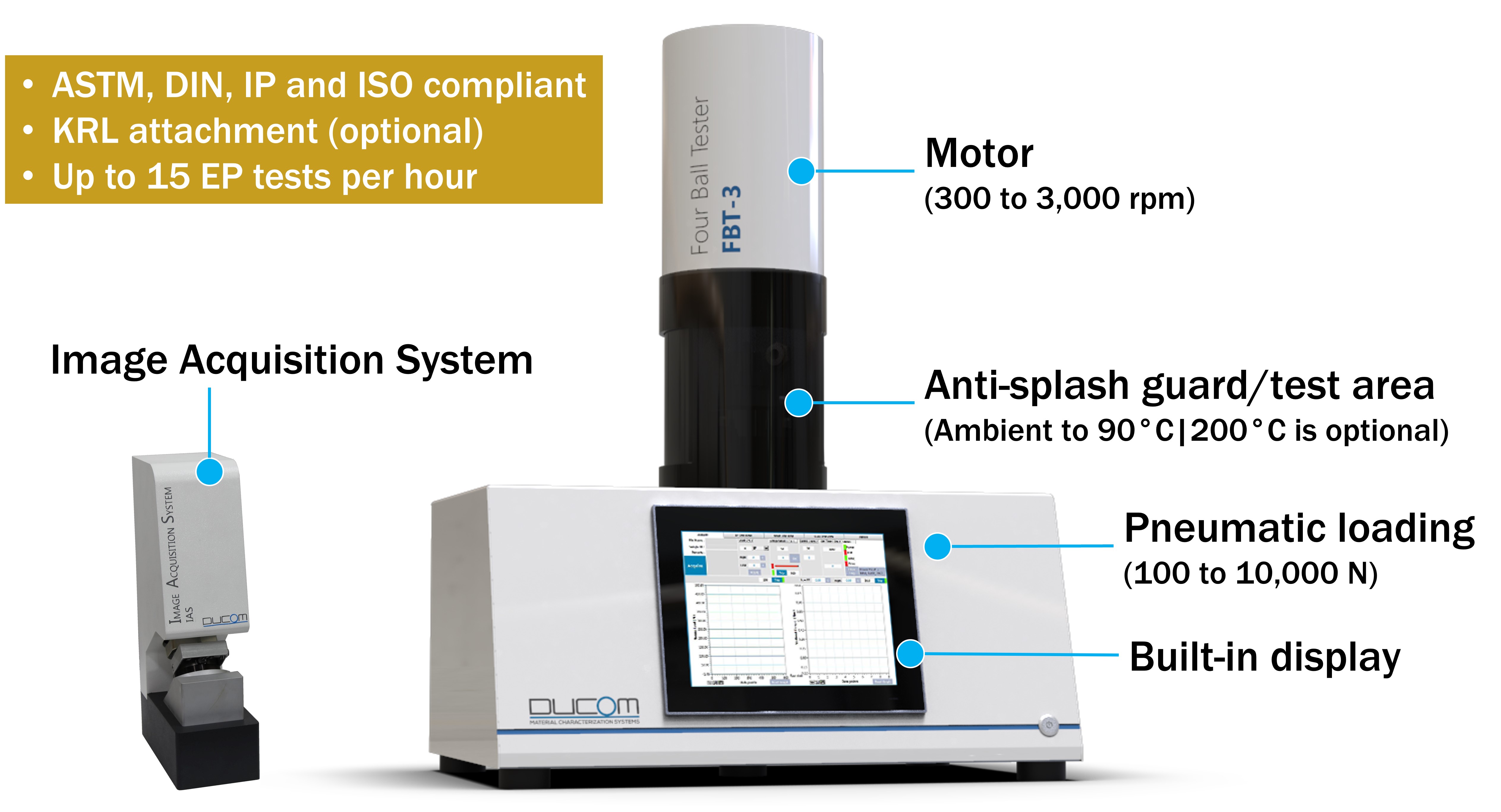

Figure 1. Description of the Ducom Four Ball Tester (FBT-3) with Image Acquisition System (IAS).

Figure 1. Description of the Ducom Four Ball Tester (FBT-3) with Image Acquisition System (IAS).

In this study, we have developed a short duration test method using a four-ball tester or FBT-3 (see Fig. 1). The FBT-3 is powered by automation and artificial intelligence, to quickly measure friction and wear of oils with an exceptional repeatability. The total duration of a single test was kept below 8 minutes, including test setup, oil heating, cleaning of ball pot, imaging, and measurement of ball wear scars.

REPEATABILITY IS THE KEY. Table 1 shows the test parameters selected to prove the precision of FBT-3 results. Two fresh synthetic wind turbine gear oils were tested under 1000 N load and 1420 rpm spindle rotation. The test duration was 60 seconds, and the oil samples were heated up to 75°C. Ball pot design with low thermal mass enabled quick heating of oils within 5 minutes (initial oil temperature was 25+1°C). Each oil was tested two times.

Table 1. Test parameters./Images%20for%20Blogs/Table%201_Test%20parameters%20Oelcheck%20DOE_v4.jpg?width=595&name=Table%201_Test%20parameters%20Oelcheck%20DOE_v4.jpg)

Average friction and mean ball wear scar diameter (MWSD) were measured for each oil. The representative images are shown in Figure 2.

/Images%20for%20Blogs/MWSD_Test%201%20and%20Test%202_v5.jpg?width=696&name=MWSD_Test%201%20and%20Test%202_v5.jpg) Figure 2. Ball mean wear scar diameters obtained from FBT-3.

Figure 2. Ball mean wear scar diameters obtained from FBT-3.

Results in Table 1 show that there is a high precision in friction coefficient measurement and also in determining MWSD. This precision can be attributed to automation in FBT-3 and MOOHA AI enabled image analysis.

Table 2. Summary of friction coefficient and mean wear scar diameter values for wind turbine gear oils./Images%20for%20Blogs/Table%202_Test%20results%20COF%20and%20MWSD_v3.jpg?width=800&name=Table%202_Test%20results%20COF%20and%20MWSD_v3.jpg)

ICP – FRICTION – WEAR. This high precision test method was now used to investigate the relationship between ICP and FBT-3 determined properties of gear oils. These gear oils were extracted at various in-service hours from different wind turbines. In this preliminary investigation, the oils were tested at ambient temperature. The comparison between ICP derived composition, FBT-3 determined friction and wear is shown in Figure 3. There is a correlation between ICP additive composition (ZDDP) and FBT-3 friction and wear for all the gear oils, as there is an increase in additives being depleted we could see that there is an increase in the oils friction and wear.

/Images%20for%20Blogs/ICP_COF_Wear_v1.jpg?width=15949&name=ICP_COF_Wear_v1.jpg) Figure 3. Comparison between the ICP analysis and Four Ball Tester for aged gear oils. (A) ICP determined Zinc dialkyldithiophosphates (ZDDP) composition at different service hours or oil ageing. Relationship between ZDDP content and (B) average friction coefficient and (C) average MWSD for the three aged gear oils.

Figure 3. Comparison between the ICP analysis and Four Ball Tester for aged gear oils. (A) ICP determined Zinc dialkyldithiophosphates (ZDDP) composition at different service hours or oil ageing. Relationship between ZDDP content and (B) average friction coefficient and (C) average MWSD for the three aged gear oils.

In this study, we proved that a 60 second four ball test is a precise and reliable tribological test method [1] for its comparison with the ICP derived additive depletion [2].

Related articles:

Contact us for more information. Our experts are just a click away.

These Stories on wear

USA: +1 (847) 737-1590

India: +91 (80) 4080-5555

Netherlands: +31 (85) 065 74 10