.jpg)

Electric vehicle lubricants or e-fluids/greases must comply with more specifications compared to the conventional fluids/greases used in IC engine. A new generation of component test rigs relevant to fully electric vehicles (EV’s) have become essential for lubricants industry where most of its R&D spending is to compete and create value in EV’s market space. In this regard the Society of Tribology and Lubrication Engineers or STLE has organized an event (EV Conference) that gathers industrial and academic experts to share their views and experience on EV tribology.

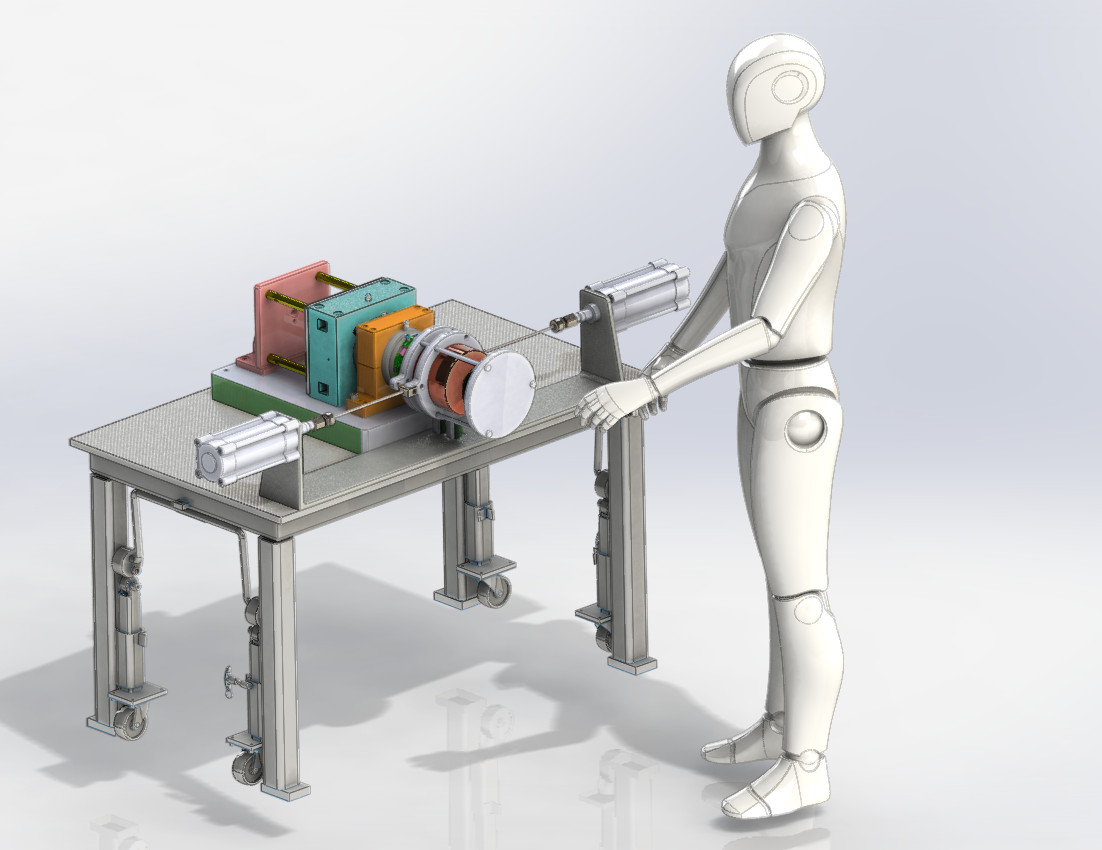

Ducom Instruments has invested in a new line of Electrical Lubricant Test Rigs (ELT's) that can address all the critical test parameters required for qualifying fluids and greases used in lubricating electric drive train components. When STLE EV committee approached us to share our views on ELTs, we got excited and to honor their request we planned to launch our High Speed Bearing Test Rig (see Figure 1) - a key product within Ducom ELT's.

On Friday 5th November (session 5: Lubricant Testing for EVs), we will present our innovative product design of two stage lubricated bearings that can be tested up to 30,000 rpm and at load up to 15 kN. Bearings can be lubricated with grease or oils, that can be heated up to 150 °C using our proprietary heat exchanger. Rotor dynamics and cooling system are key techniques to reduce its downtime and improve safety of the operator.

Electrical Lubricants Test Rig is the first in market that is aimed at creating high value lubricants for better performance of EV’s and empower the idea of reducing carbon emission through electrification.

Electrical Lubricants Test Rig is the first in market that is aimed at creating high value lubricants for better performance of EV’s and empower the idea of reducing carbon emission through electrification.

We will elaborate on those techniques during the presentation. Each bearing station is embedded with smart sensors that capture the vibration, noise, bearing friction and temperature of the lubricated system. The sensor system is MOOHA-enabled: it completely automates the process of data collection, cloud storage, analytics, and reporting. Collectively they provide insight to e-grease or e-fluid performance (i.e. antiwear, thermal conductivity, friction and fatigue resistance). In the presentation, we will share a case study that describes the performance of few electrical lubricants that are widely used in electric motor and wheel hubs of battery-powered EV’s.

Join our virtual presentation at STLE "Tribology and Lubrication for E-Mobility"

Contact us for more information. Our experts are just a click away.

USA: +1 (847) 737-1590

India: +91 (80) 4080-5555

Netherlands: +31 (85) 065 74 10