Ducom Instruments is proudly participating in the 2021 edition of the STLE Annual Meeting & Exhibition, held virtually in May 17-20, 2021.

The event is an annual conference organized by the Society of Tribologists and Lubrication Engineers (STLE). STLE is a technical society that unites individuals and companies that share an expertise in tribology and lubrication.

Ducom will present its findings spread over five different technical presentations during this edition of STLE. Our findings are diverse and it ranges from materials (Ex. renewable alternatives to diesel fuels, biomedical coatings) to instrumentation (establishing precision limits for friction and wear at 1000 °C) .

The presentations are pre-recorded and will be made available online during the conference. After registering, you will be able to (re)watch the presentation at your convenience for the next 90 days through the STLE on-demand platform.

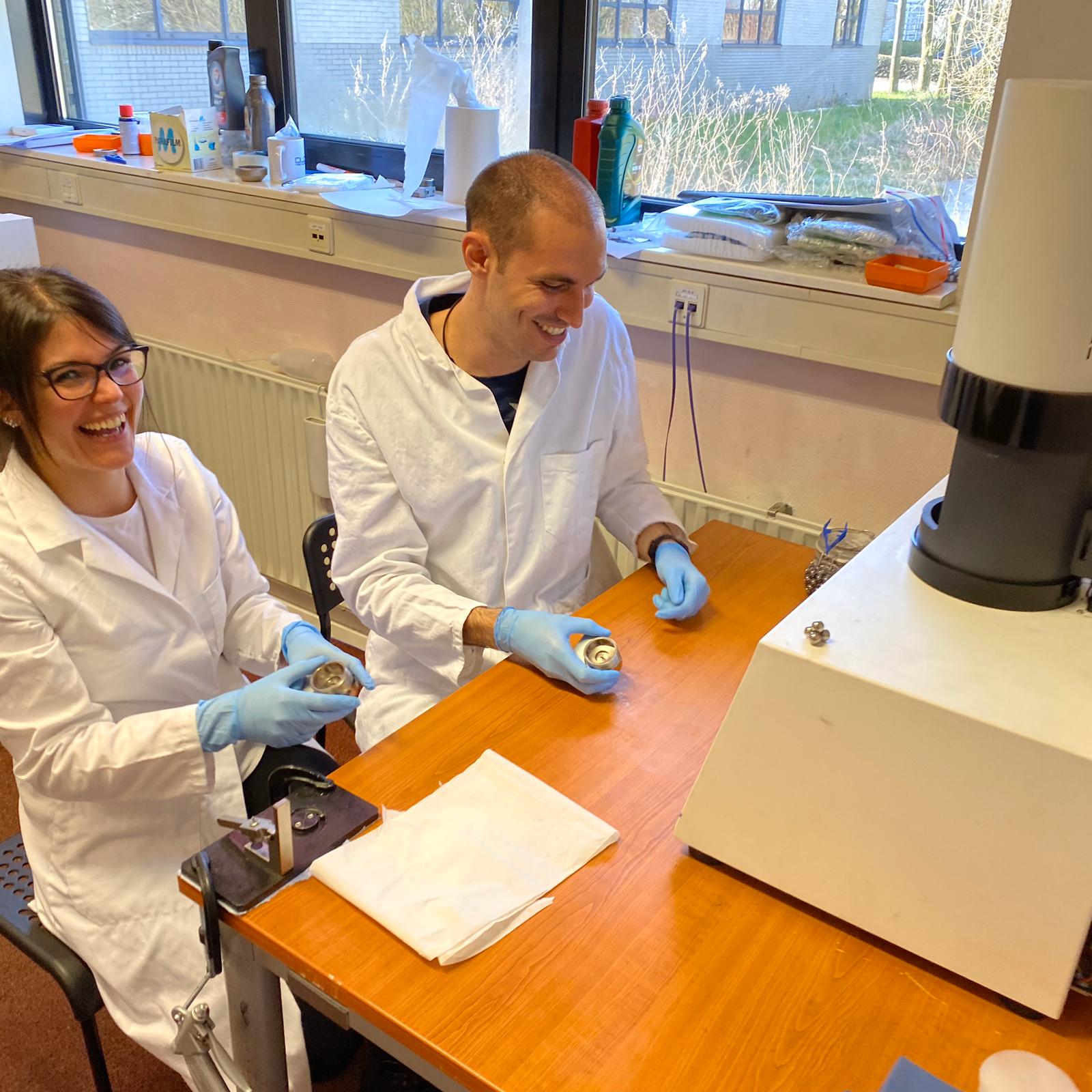

The results that will be presented were generated by the Ducom Global Applications Team in our in-house tribology laboratory spread over three countries (India, Netherlands and USA). In the paragraphs below you can read more about the presentations that were chosen by STLE.

Lubricity Behavior of HVOs

Available online from Monday, May 17 at 2:30 PM (GMT -4)

Hydrogenated vegetable oils with insufficient lubricity introduced to injection equipment can result in noncompliance with ASTM D975 or EN 590.

We used High Frequency Reciprocating Rig (HFRR) to investigate the friction and wear behavior of neat HVOs and additized HVOs. Read more.

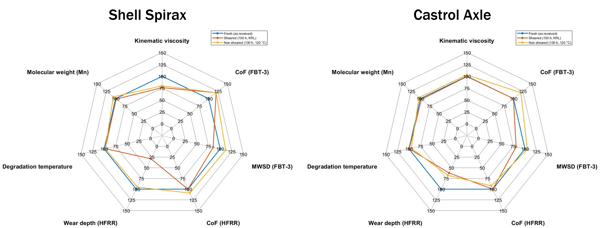

Laboratory Aging of Ester Oils and Its Effect on Friction and Wear

Available online from Tuesday, May 18 at 11:00 AM (GMT -4)

Field tests to determine the aging of lubricants are expensive and time consuming. We modified the CEC L-45-99 in KRL Shear Stability Tester to age oils and establish degradation of additives using both tribological (FBT-3 and HFRR) and analytical techniques such as FTIR, Gas Permeation Chromatography and Thermogravimetric Analysis. Read more

Repeatability of Friction and Wear of Different Material Pairs at 1000 °C under Unidirectional Sliding Motion

Available online from Wednesday, May 19 at 2:00 PM (GMT -4)

Repeatability and reproducibility parameters in a high temperature tribometer must be established before screening high entropy materials. In this study we have used high temperature pin on disc - POD 4.0 to identify the reference materials to be used for measuring the repeatability of friction and wear at 1000 °C. Read more.

Wear of Antibacterial Coatings on CoCrMo under Butterfly Motion and Dynamic Loads in a Biotribometer

Available online from Wednesday, May 19 at 2:30 PM (GMT -4)

Relevant benchtop tests for biomaterials should reproduce the in-vivo load, motion and environment. We have evaluated two antibacterial coatings on CoCroMo under physiological dynamic loads in a BioTribometer and cross shear to establish their wear rates.

A System Engineering Approach to Reduce Soot Wear

Available online from Thursday, May 20 at 10:30 AM (GMT -4)

Soot contamination in engine oil results in increased friction and wear of engine components. A High Frequency Reciprocating Rig (HFRR) was used to evaluate the effect of soot contamination in commercially available engine oils and its effect on the friction and wear behavior of lubricants. The effect of steel preconditioning and the coating of mating surfaces with DLC were also evaluated. Read more.

Contact us for more information. Our experts are just a click away.

USA: +1 (847) 737-1590

India: +91 (80) 4080-5555

Netherlands: +31 (85) 065 74 10