Renewable sources for producing diesel fuel are on the rise. Vegetable oils, waste cooking oils and animal fats are few examples of renewables used in producing the biofuel. Although biofuel has limited our reliance on fossil fuel, it comes at an expense for the automotive industry. Biodiesel (EN 14214 standard) type like FAME (Fatty Acid Methyl Esters) produced via transesterification of vegetable oils is related to increase in the diesel NOx emission, increase in fuel consumption due to its low energy content, and poor cold operability (high cloud point and pour point) can lead to engine deterioration. However, the second-generation biodiesel produced by hydrotreatment of waste cooking oils (i.e. HVOs – Hydrotreated Vegetable Oils) have overcome these disadvantages in FAME biodiesel.

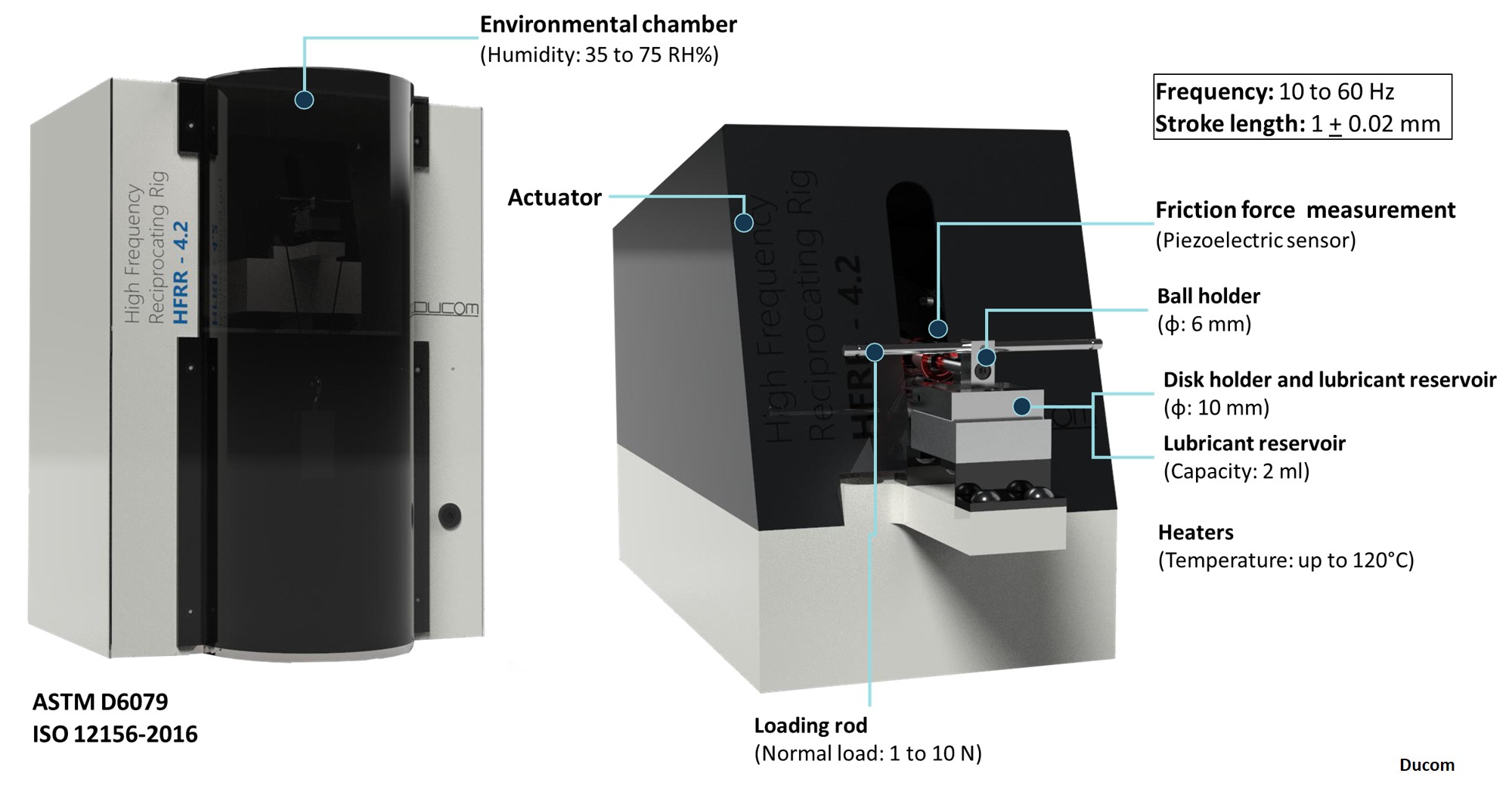

Figure 1. Description of the Ducom High Frequency Reciprocating Rig (HFRR 4.2) used in this study.

HVOs (EN 15940 standard) are straight chain paraffinic hydrocarbons without sulfur and aromatics. HVOs deliver high energy content, superior cold operability, low pollution that is attributed to its high hydrogen, absence of oxygen and low carbon, respectively. HVOs are a class of renewable diesel that is close to fossil fuel diesel (EN 590 standard), with an exception to its density. Although the HVOs without oxygen content deliver better cold flow properties that is much needed to high performance of fuel injection system, its poor lubricity behavior can have negative impacts on engine components. Poor lubricity by HVOs can be also attributed to the absence of sulfur.

HVOs with insufficient lubricity introduced to injection equipment can result in noncompliance with ASTM D975 or EN 590.

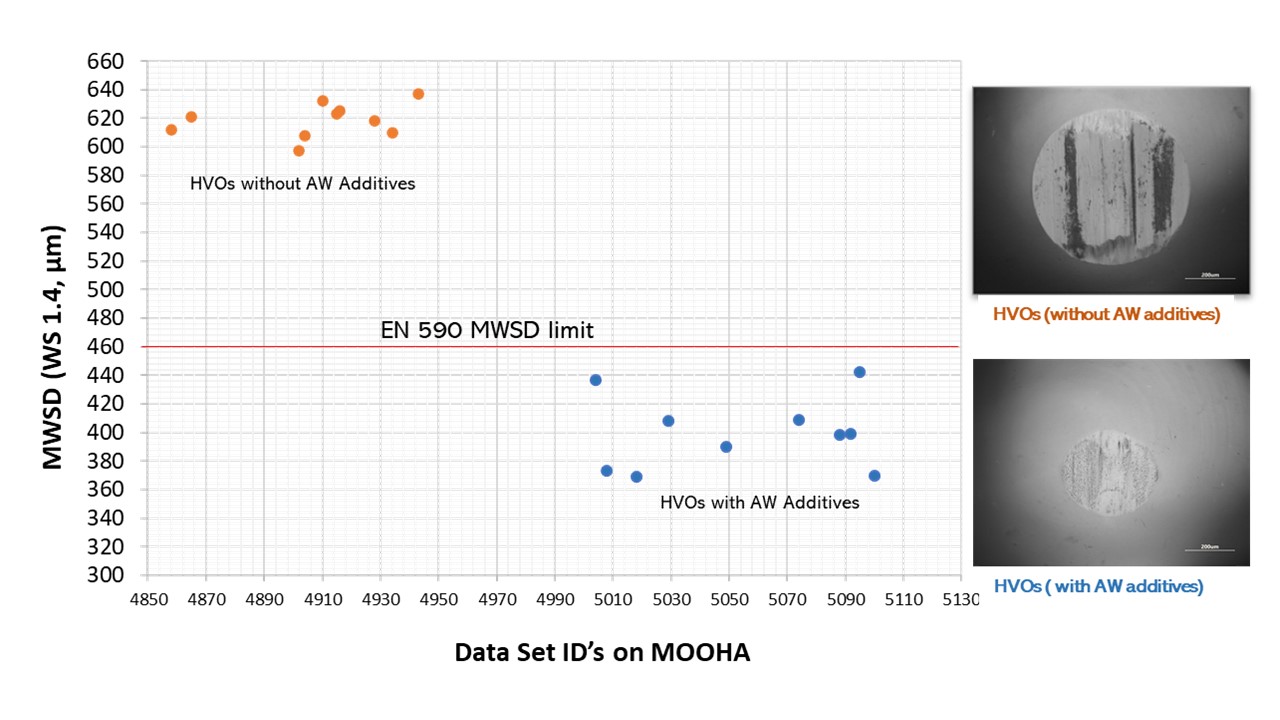

Figure 2. Graph representing the ball Mean Wear Scar Diameter (MWSD) for HVOs with and without AW additives. Ducom HFRR enabled with MOOHA was used for lubricity test according to ISO 12156. Total 20 tests were conducted, ten each for HVOs with or without AW additives. All the test data were automatically logged in a digital data log book provided by MOOHA.

Therefore, HVOs are blended with antiwear (AW) additives to comply with lubricity factor specified in D975 and EN 590. High Frequency Reciprocating Rig (HFRR) is used to screen AW additives compatible with HVOs and also for quality control of fossil fuel diesel blended with HVOs.

As shown in Figure 1, the HFRR is a bench top tribometer comprised of voice coil actuator used for precision control of frequency and amplitude, salt free humidity control, localized fluid heating and temperature control system, piezosensor and flexure system for friction measurement and linear deformation sensor for inline stroke length calibration. This design is in compliance with ASTM D6079 and ISO 12156.

Ducom HFRR is frequently benchmarked against PCS HFRR in ASTM proficiency testing program (PTP)/ round robin test program. Please contact us for relevant reports.

HFRR ball wear scar diameter (MWSD) measured according to fuel lubricity test standards like ISO 12156-1 or ASTM D6079 is used to check the HVOs compliance with EN 590 or D975. In this HFRR study according to ISO 12156, we have tested ten samples of HVOs without AW additives and ten samples of HVOs with AW additives. HFRR ball and disks specimens were donated by Pacific Sensor.

As shown in Figure 2, the average Ball MWSD for HVOs without AW additives was 618 μm ( N = 10, precision at 33 μm) and for the HVOs with AW additives it was 399 μm (N = 10, precision at 26 μm). Please note that all the ASTM relevant statistics described in this study was automatically generated using MOOHA. Fossil fuel diesel sold in EU should comply with MWSD maximum limit of 460 μm, according to EN 590. The AW additives used in this study has improved the lubricity of HVOs, it has enabled HVOs to comply with EN 590.

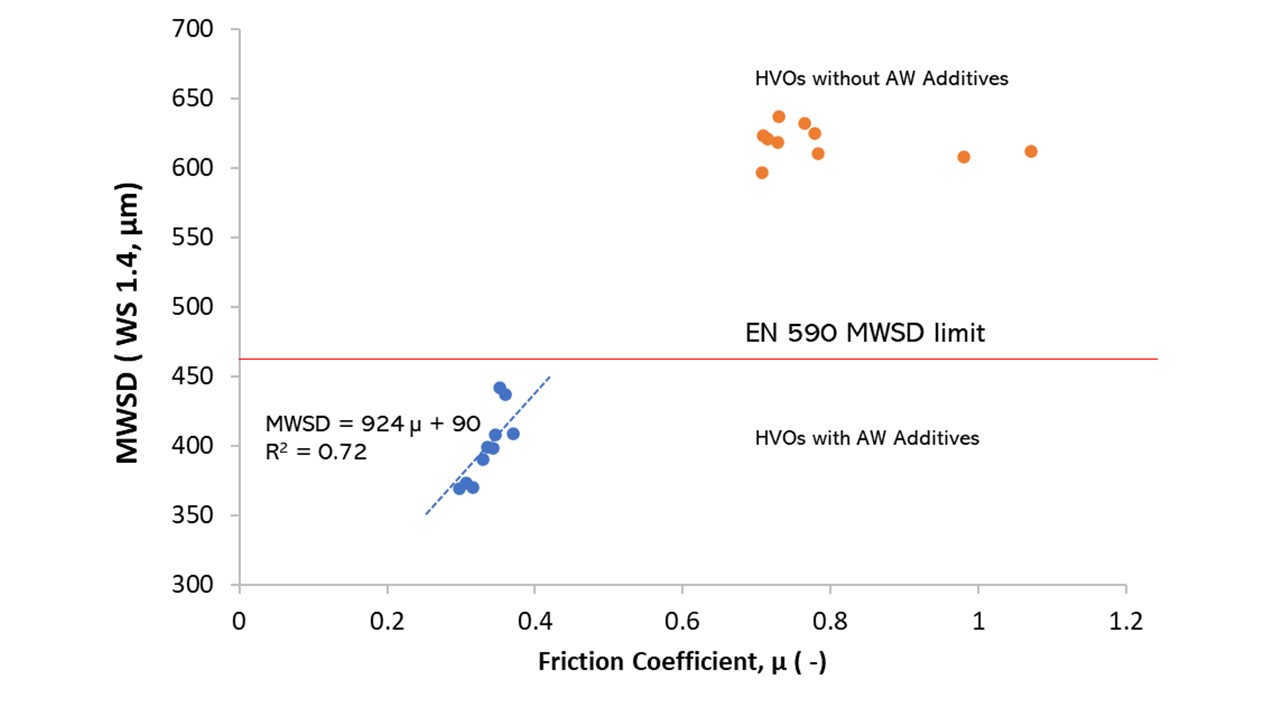

Figure 3. Graph representing the relationship between ball Mean Wear Scar Diameter (MWSD) and friction coefficient for HVOs with and without AW additives. Ducom HFRR enabled with MOOHA was used for lubricity test according to ISO 12156. Total 20 tests were conducted, ten each for HVOs with or without AW additives. All the test data were automatically logged in a digital data log book provided by MOOHA.

In Figure 3, we have reported an interesting observation on the relationship between friction and wear for HVOs. In the case of HVOs with AW additives there is a linear relationship between wear and friction, however there is no such relationship for HVOs without AW additives. This confirms that AW additives used to lower the wear can also lower the friction. Low friction in fuel pump will decrease its overall power consumption. Surprisingly the friction coefficient for some HVOs without AW is above 0.7, that represents the seizure of any lubricated system.

In conclusion, the AW additives compensate for poor lubricity by HVOs due to absence of oxygen and sulfur. HVOs with AW additives comply with EN 590 MWSD limit, as determined using Ducom HFRR and MOOHA. Thus, HVOs with AW additives compared to FAME biodiesel is more suitable as drop-in fuel.

Contact us for more information. Our experts are just a click away.

USA: +1 (847) 737-1590

India: +91 (80) 4080-5555

Netherlands: +31 (85) 065 74 10