‘God made the bulk, surfaces were created by the devil' said Wolfgang Pauli hinting at the complexity of surface interactions.

Energy dissipated in a system with moving components can be affected by the surface roughness, hardness, tension, distribution and geometry of asperities in contact (plasticity index). These surface parameters evolve in a system due to pressure, temperature and velocity of components in motion. Dynamic changes in surface parameters has to be monitored in situ or in its nature state, that can unravel the natural relationship between surface parameters, energy dissipation and system failure. This can be achieved by mastering the scientific instrumentation for in situ tribology.

For in situ tribology, the scientific instruments for surface characterization like profilometry, spectroscopy have to be integrated into the platform used for friction and wear measurements.

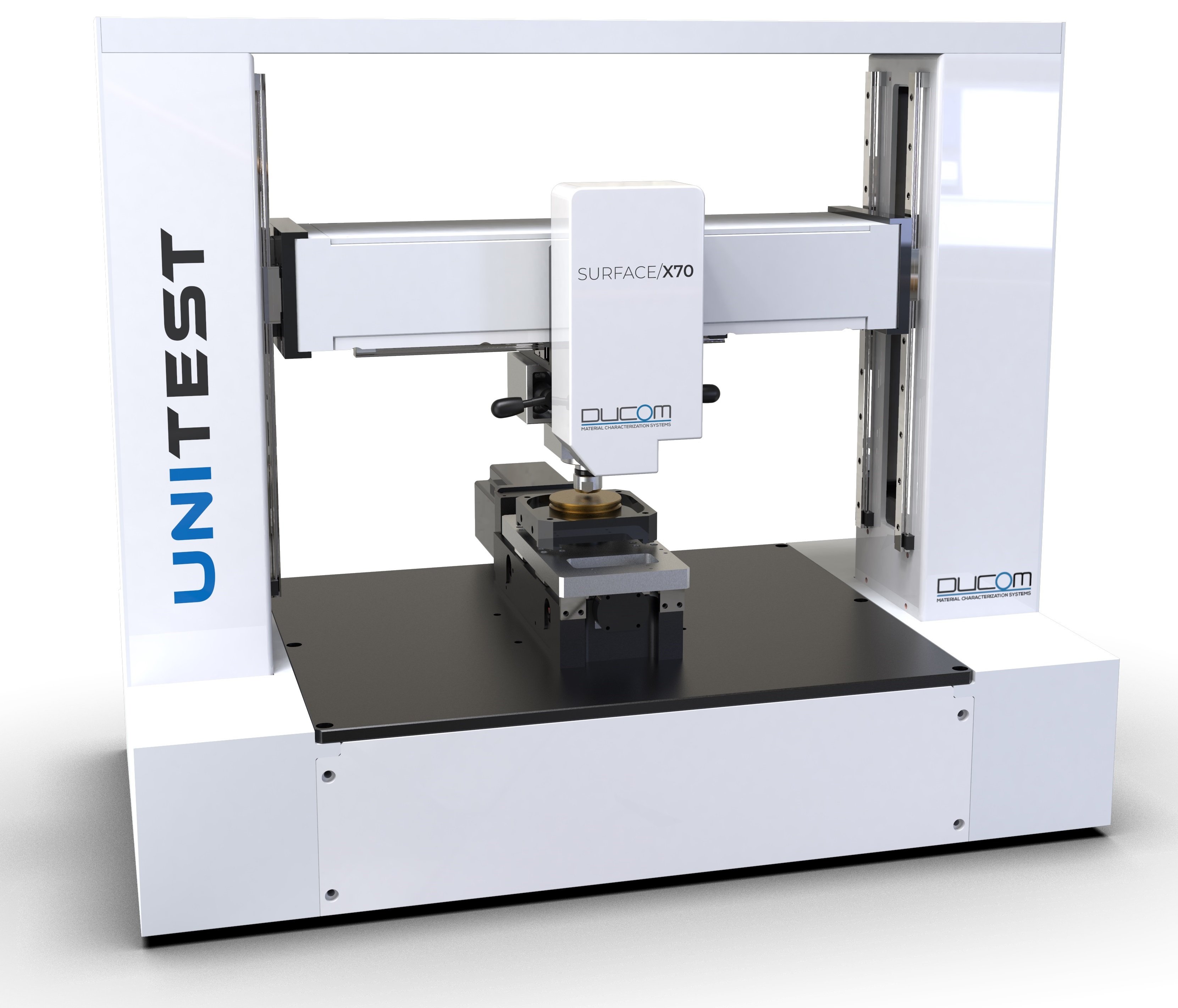

Ducom Unitest is a universal tribometer with in situ characterization techniques, this is a highly advanced open platform capable of ‘symbiotic integration’ of several surface characterization probes such as mechanical testing, surface imaging and spectroscopy. The tribometer offers multiple interchangeable load and motion combinations for diverse research i.e., from scratch and indentation modules to rotary, linear reciprocation and fretting modules all the way to advanced multi-directional, dynamic load bio-tribology modules. (see Figure 1)

Figure 1. Unitest open platform with configurable load, motion, environmental and imaging modules

The highly precise stage works seamlessly to position the sample under multiple diagnostic probes. Figure 2 represents one among many possible configurations, featuring a linear motion module with a 3D non-contact profilometer head mounted on the moving Z-Axis beam for in-situ profilometry.

Figure 2. Unitest with a linear motion stage for reciprocation wear integrated with a surface imaging head - non-contact profilometer. This profilometer can measure sample roughness and its wear volume.

In this guide, we deep dive into established techniques, summarize the capabilities and highlight limitations from the perspective of surface characterization and tribology research. Three of the most common techniques used for non-contact optical profilometry are focus variation, confocal microscopy and white light interferometry which rely on different working principles viz.,

With several profilometers being offered with universal tribometers, selection of the right technology can be daunting for the tribologists.

Focus variation is a conventional optical microscopy technique that relies on Z-direction vertical scanning and integration of multiple in-focus images to get a true color and 3D surface topography. It offers fast scanning speeds of several mm/sec.

Confocal microscopy is also a conventional optical microscopy technique that uses a small pin hole to block out-of-focus light to achieve high vertical resolution upto 1 nm.

Interferometry relies on the interference pattern created by two beams of light (one reference and another reflected off the sample) which differ either in optical path difference or phase difference to achieve sub-nm resolution.

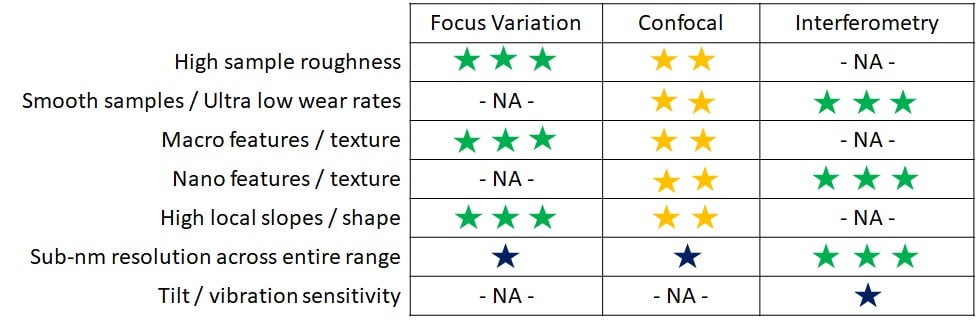

Please look into the Table 4 that summarizes the relevance of these capabilities in the context of surface characterization and tribology.

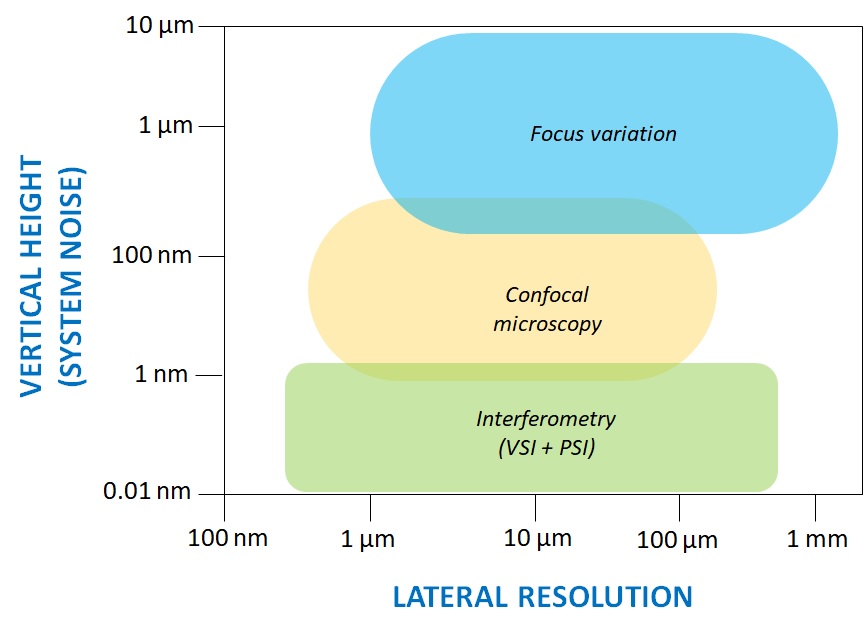

Figure 3. A 2D map of the vertical height capability and lateral resolution of different profilometry techniques

An easy to interpret 2D map of the lateral and vertical resolution capability of different techniques is shown in Figure 3. Note the logarithmic scales with vertical resolution spanning several orders of magnitude in spatial resolution. The vertical resolution is limited by system noise, with moving assemblies such as spinning discs and galvanometric mirrors having higher noise compared with digital scanning technologies.

Table 4. Selection of different techniques for samples exhibiting a wide range of surface textures, roughnesses and wear rates. (Note that - NA - means not applicable and the technique cannot be used)

It is evident that there is no 'Universal' technique for surface topography characterization to understand its effect on tribology. For example, the micro-textured surfaces having specific shapes and geometry show ultra-low wear rates due to transition in lubrication mechanism, this investigation will require a combination of techniques such as focus variation and interferometry (reference to Table 4). The use of conventional profilometers in a Universal Tribometer can yield poor results due to the unacceptable noise floor.

However, Ducom profilometer is highly versatile as it features 3-in-1, focus variation, confocal and interferometry techniques in a single head thereby connecting different length scales and spatial resolution and can adapt to any tribological application requirements. Moreover, X-Y scanning across larger areas uses digital raster methods and not traditional spinning disc methods. One can draw an analogy between a conventional hard disk drive (HDD) vs. solid state drive (SSD).

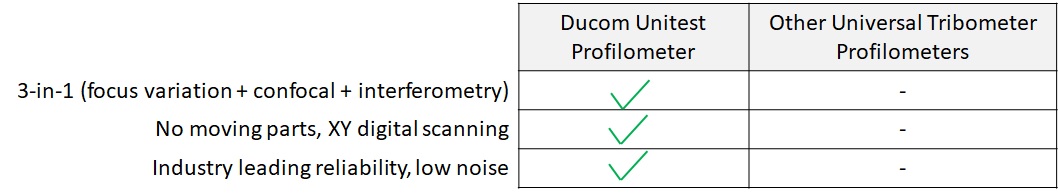

In situ Profilometer (Ducom Unitest) has no moving parts, this system guarantee industry leading accuracy, low noise floor, faster response time and virtually zero maintenance (refer to Table 5)

Table 5. Comparison of Ducom profilometer with other technologies offered in Universal Tribometers

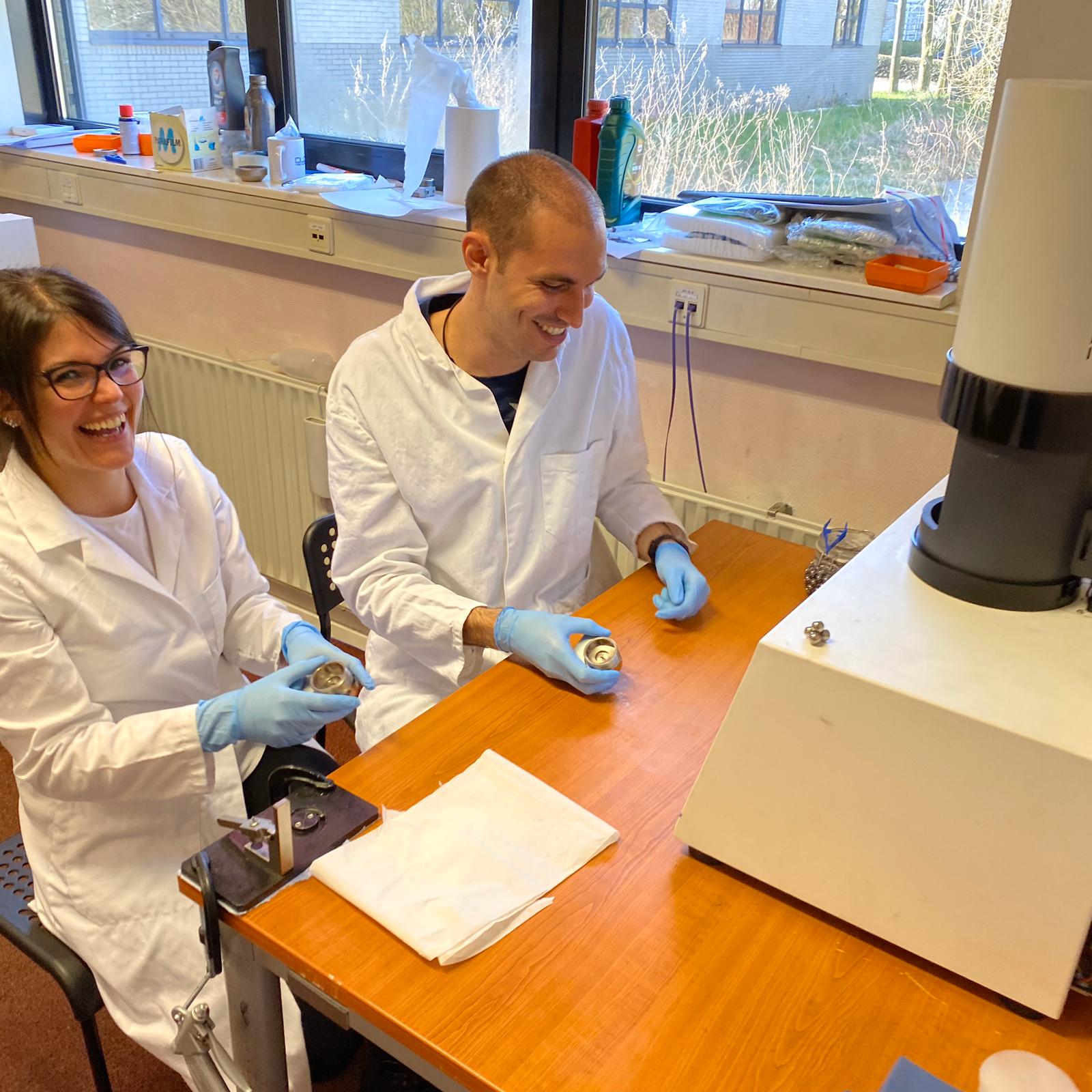

Our customer experience shows that the Ducom Unitest open platform with in-situ profilometer offers the highest standards for diverse tribology research and surface characterization, connecting surface topography across multiple length scales from sub-nm to several mm.

Contact us for more information. Our experts are just a click away.

These Stories on UniTest

USA: +1 (847) 737-1590

India: +91 (80) 4080-5555

Netherlands: +31 (85) 065 74 10