Materials used in brake system should enable stable friction, reduce wear and its related airborne particles. A team led by Prof. Straffelini and Prof. Gialanella in University of Trento is using Ducom Multi Capability Tribometer (POD 4.0) to develop novel brake materials that can reduce airborne wear particles by 50 %; a stringent standard set up by European LOWBRASYS community.

Materials used in brake system should enable stable friction, reduce wear and its related airborne particles. A team led by Prof. Straffelini and Prof. Gialanella in University of Trento is using Ducom Multi Capability Tribometer (POD 4.0) to develop novel brake materials that can reduce airborne wear particles by 50 %; a stringent standard set up by European LOWBRASYS community.

What are the tribology-related activities in Univ. of Trento’s laboratory?

Prof. Straffelini: “Our team in Trento is focused on tribology of materials in dry sliding conditions. This includes the braking system with a brake pad and brake disk in dry contact at temperature above 200°C. This is a part of LOWBRASYS project funded by Horizon 2020. Our mission is to develop environment friendly braking materials, either by reducing the particulate matter released by current braking materials or by introducing new low-pollutant braking materials. The goal is to apply tribology to improve air quality in Europe by reducing the airborne particulate matter by 50% compared to the current level”.

Why did you choose Ducom Multi Capability Tribometer?

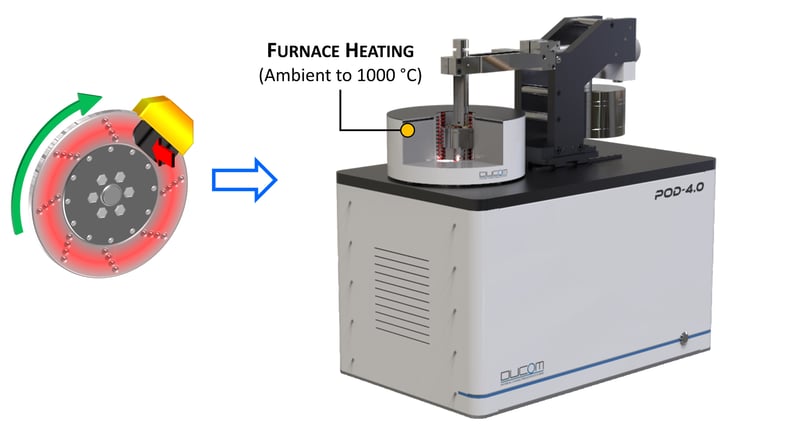

Prof. Straffelini: “Thermomechanical load during the braking events generates friction heat that is translated into wear. Brake materials fade during this process where the heat distribution is not uniform between the brake pad and brake disk (see Fig. 1). Simulating this differential heat state in a friction testing device (so called “Tribometer”) was difficult. We chose Ducom POD 4.0 because of its novel heating design (see Fig. 1)".

Figure 1. Schematics of a brake pad system (left) and Ducom POD 4.0 (right), with ariborne particles collection.

Figure 1. Schematics of a brake pad system (left) and Ducom POD 4.0 (right), with ariborne particles collection.

How does Ducom POD 4.0 add value to your research?

Prof. Straffelini: “Brake system used in vehicles are prior subjected to testing at materials and component level. Both are complimentary to each other. Materials testing in a tribometer is cheaper than component testing in a dynamometer or vehicles on the field. Effective materials testing in a tribometer that closely simulates the braking conditions in the field reduces the cost of product development. Therefore, Ducom POD 4.0 has been very useful. It has reduced the iterations of materials-to-component level testing. Furthermore, it adds a unique value because of the environment chamber that allow collection of airborne particles during the “fade performance” test of materials (see Fig. 1).

These Stories on high temperature

USA: +1 (847) 737-1590

India: +91 (80) 4080-5555

Netherlands: +31 (85) 065 74 10