The automotive industry has undergone a revolutionary shift with the rise of electric vehicles (EVs) in the pursuit of sustainable transportation. While EVs promise a cleaner future, they present challenges for the lubricant industry. As traditional engines give way to electric powertrains, lubricants play a critical role in ensuring optimal performance and longevity. EVs require specialized formulations for electric motors, gear systems, and bearings. The transition to electric mobility demands cutting-edge lubricants with enhanced thermal stability, conductivity, and anti-wear properties to address challenges like higher temperatures and increased power density. The industry is adapting to these needs to ensure optimal efficiency and durability in EVs.

Standard testing methods may fall short in accurately gauging the performance of lubricants in electric vehicles. In this study, we evaluated the anti-wear, extreme pressure properties and viscosity loss of two different EV fluids according to widely used ASTM and CEC test standards. In this chapter we will discuss the CEC L 45-99 test results obtained using the KRL attachment to FBT3 (see Figure 1) integrated with the Ducom Four Ball Tester (FBT-3).

Figure 1. Ducom Four Ball Tester (FBT-3) with KRL Shear Stability Tester attachment.

Two different EV fluids with high and low viscosity were selected fro this study (see Table 1).

| Unit | Low viscosity | High viscosity | |

| Kinematic Viscosity (100 °C) | cSt | 7.5 | 9.0 |

| Density | kg/m3 | 950 | 950 |

| Flash Point | °C | 200 | 200 |

According to the CEC L-45-99 standard, the fluid under test must be sheared for 20 hours under high load (5000 N) and high speed (1475 rpm) conditions. The temperature was kept at 60±1 °C. The same fluids were sheared under the same test condition for an extended duration of 200 hours. After each test, the viscosity of the fluid was measured and compared to the viscosity of the non-sheared fluid to calculate the viscosity loss.

User-friendly: Transition effortlessly from the four-ball tester to the KRL shear stability tester in under 5 minutes.

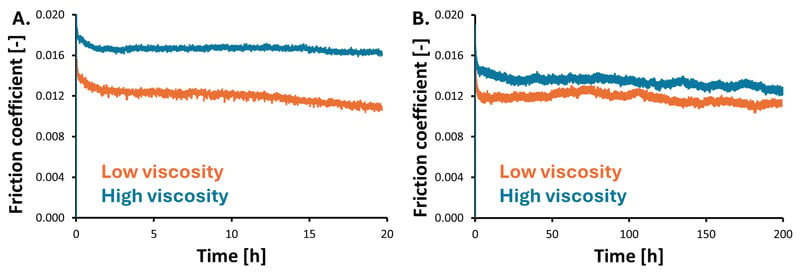

A unique feature of the Ducom KRL attachment is the friction measurement capabilities. Friciton measurement is not a requirement of the CEC standard. However, friction coefficient can be an insightful parameter along with viscosity loss. Figure 2 shows the friction coefficient behaviour of the fluids sheared for 20 and 200 hours (Figure 2A and 2B, respectively). In both cases, the high viscosity fluid showed higher friction compared to the low viscosity fluid.

Figure 2. Fricion coefficient of low and high viscosity fluids after 20 and 200 hours shearing in KRL shear stability tester.

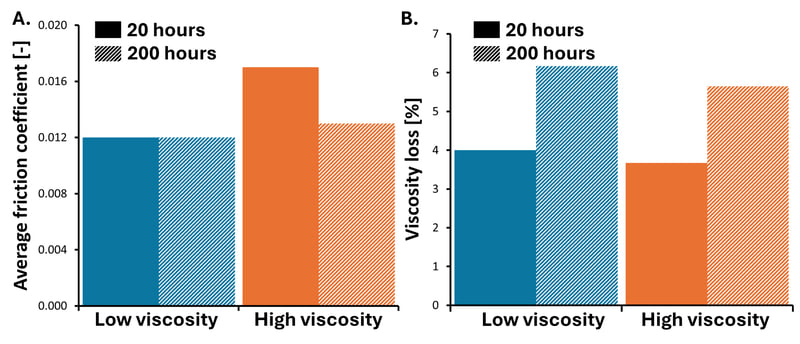

The average friction coefficient (see Figure 3A) of the low viscosity fluid was 0.012 for both test durations; the friction coefficient of the high viscosity fluid was 0.017 and 0.013 for 20 hour and 200 hours tests, respectively. The viscosity loss (see Figure 3B) of the low viscosity fluid was 4% and 6.17% for 20 hour and 200 hours tests, respectively. The viscosity loss of the high viscosity fluid was 3.67% and 5.65% for 20 hour and 200 hours tests, respectively.

Figure 3. Average friction coefficient (A) and viscosity loss (B) of low and high viscosity fluids after 20 and 200 hours shearing in KRL shear stability tester.

The viscosity loss for both fluids was 1.5 times higher after shearing for 200 hours compared to the standard 20 hours test.

CONCLUSION

Our study reaffirms that lubricant performance cannot be solely assessed by traditional test standards and metrics, and there is a need for a paradigm shift in lubricant testing and formulation for electric vehicles. With the Four Ball Tester (FBT-3), among other instruments, Ducom is at the forefront of this paradigm shift to help our customers develop new solutions for the challenges that electric vehicle fluids pose to the lubricants community.

Ducom Instruments has invested in a new line of Electrical Lubricant Test Rigs (ELTs) that can address all the critical test parameters required for qualifying fluids and greases used in lubricating electric drive train components. Read more

USA: +1 (847) 737-1590

India: +91 (80) 4080-5555

Netherlands: +31 (85) 065 74 10