In the realm of tribology and lubrication research, the Twin Disk tribometer stands out as a versatile and essential instrument for studying friction, wear, and lubricant performance at different rolling/sliding conditions. This sophisticated testing system offers numerous advantages that make it a valuable investment for researchers and engineers seeking comprehensive insights into material behaviors. Here are five compelling reasons why investing in a Twin Disk tribometer can greatly benefit your research and development efforts.

Frontal view of Ducom Twin Disk Tribometer .

1. Precursor to FZG

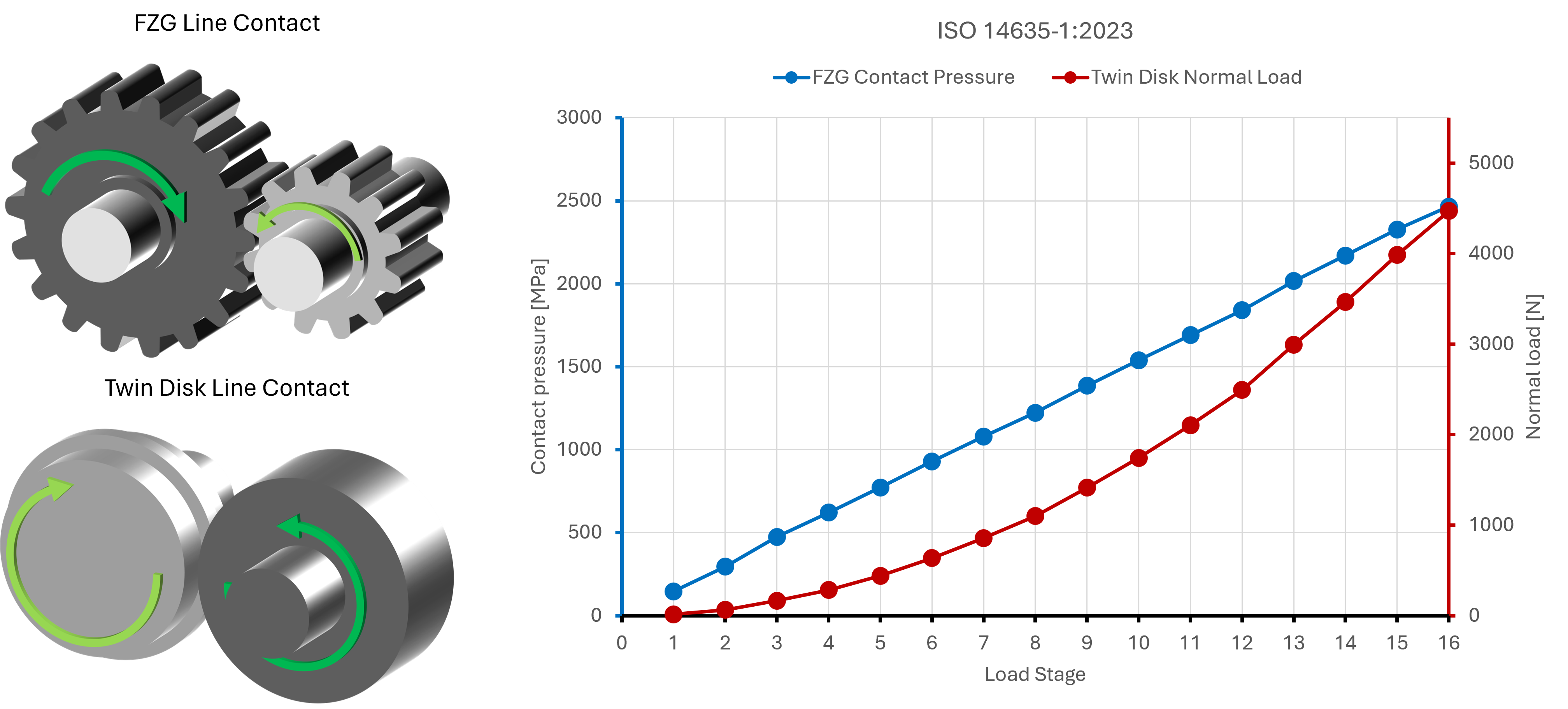

The Twin Disk tribometer serves as an excellent precursor to FZG (Forschungsstelle für Zahnräder und Getriebebau) testing, replicating key contact conditions like line contact and rolling-sliding movement encountered in FZG evaluations. This capability allows for faster and more cost-effective screening of lubricants, providing an intermediate step between formulation and full-scale FZG testing. Researchers can efficiently narrow down lubricant candidates based on initial performance, optimizing resources and time in lubrication development.

Schematics of the test contact in FZG (top left) and Twin Disk (bottom left), and Twin Disk normal loads required to achieve the contact pressures required at each step of the ISO 14635 test standard.

2. High Load Capability

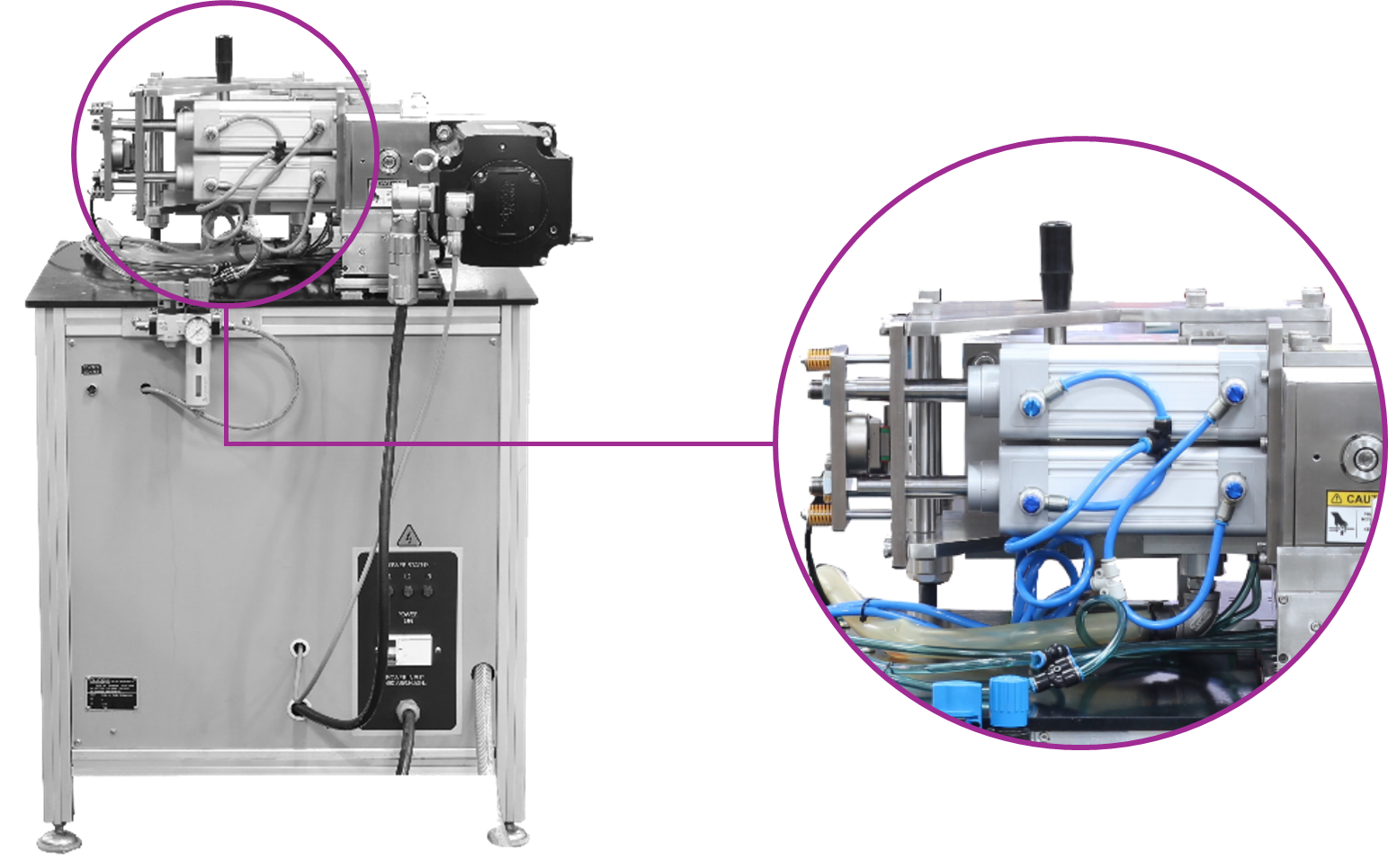

With its servo-mechanical system capable of applying loads up to 8 kN, the Twin Disk tribometer achieves high contact pressures in a steel-on-steel line contact, without the need for specialized ceramic or spherical-ended specimens. This capability ensures that test conditions closely mimic real-life scenarios, enhancing the relevance and reliability of experimental outcomes for practical applications in bearing systems, gears, and more.

Highlight of the loading system that allows Twin Disk to achieve loads up to 5 kN (8 kN with the High Load option).

3. Specimen Versatility

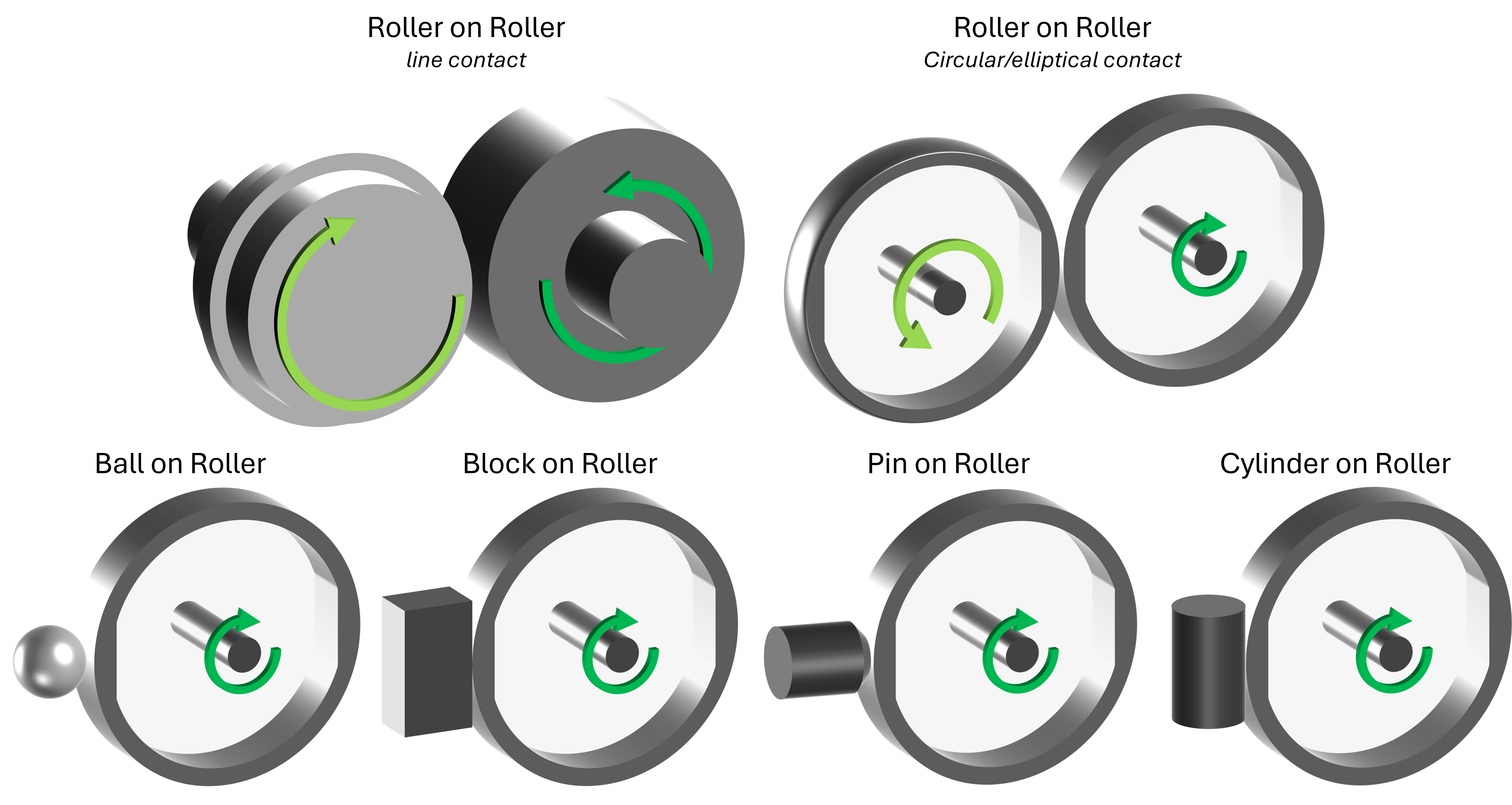

The Twin Disk tribometer offers unmatched versatility in specimen testing, accommodating various shapes and sizes including rollers, balls, pins, and blocks. This diversity allows for closer replication of real-life contact configurations, enabling researchers to explore a wider range of material interactions and lubrication performance. The ability to use different specimen shapes also facilitates easier coating and fabrication from relevant bulk materials, supporting more nuanced investigations and theoretical studies.

Schematics of all possible samples contact in Ducom Twin Disk tribometers. Switching between different geometries is possible through different sets of holders.

4. Programmable Test Profiles

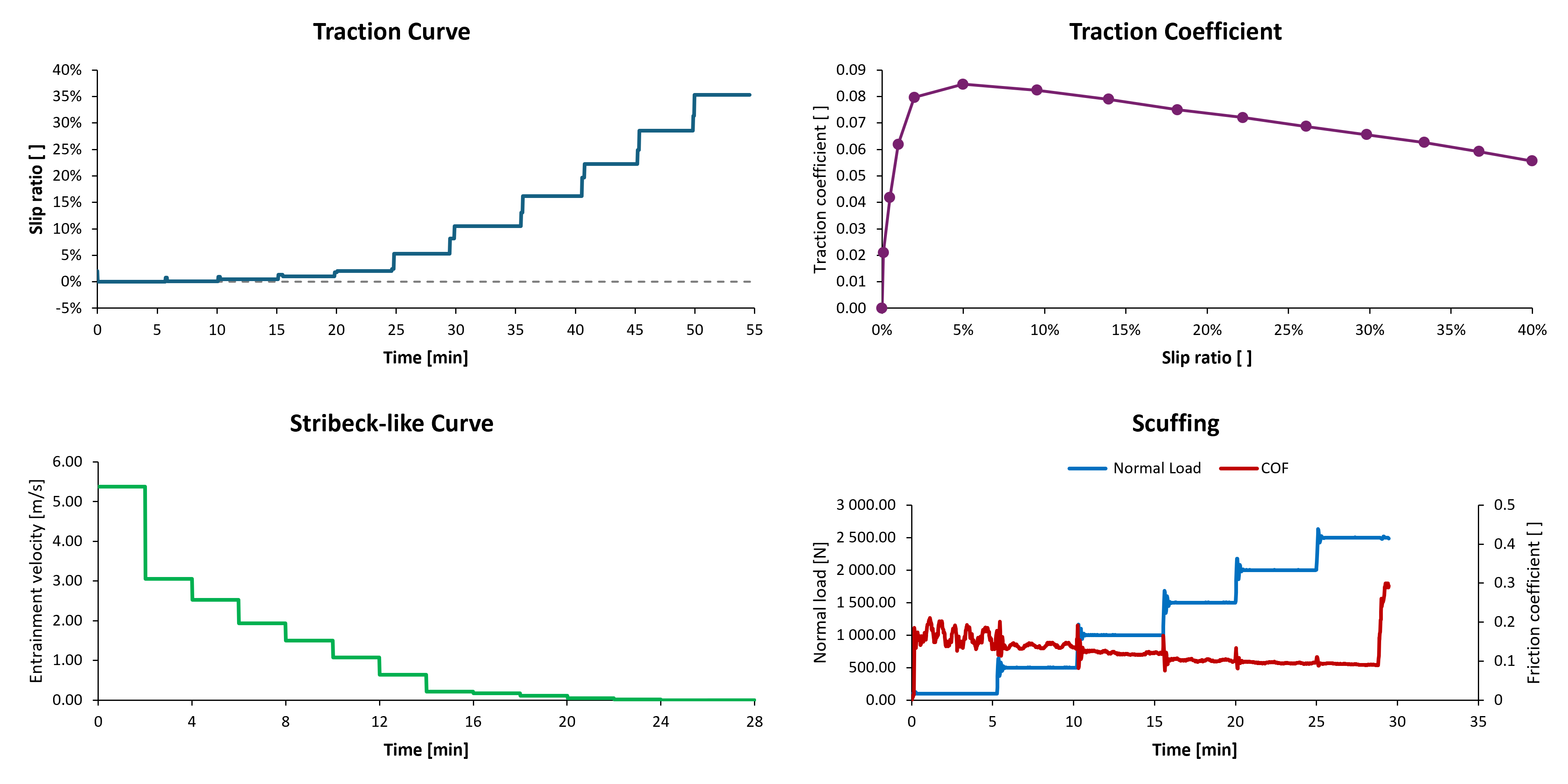

One of the standout features of the Twin Disk tribometer is its programmable test profiles, which can replicate complex interactions such as Stribeck curves, traction curves, and dynamic load profiles. This programmability enables computer-controlled sequences to simulate non-static conditions like braking or acceleration, offering insights into material behaviors under varying entrainment velocities and loads. Such flexibility empowers researchers to conduct comprehensive screening of materials and lubricants across a spectrum of realistic operating conditions.

Selection of the test profiles programmable in Ducom Twin Disk. Other standard and personalized protocols available.

5. Full Array of Controls and Sensors

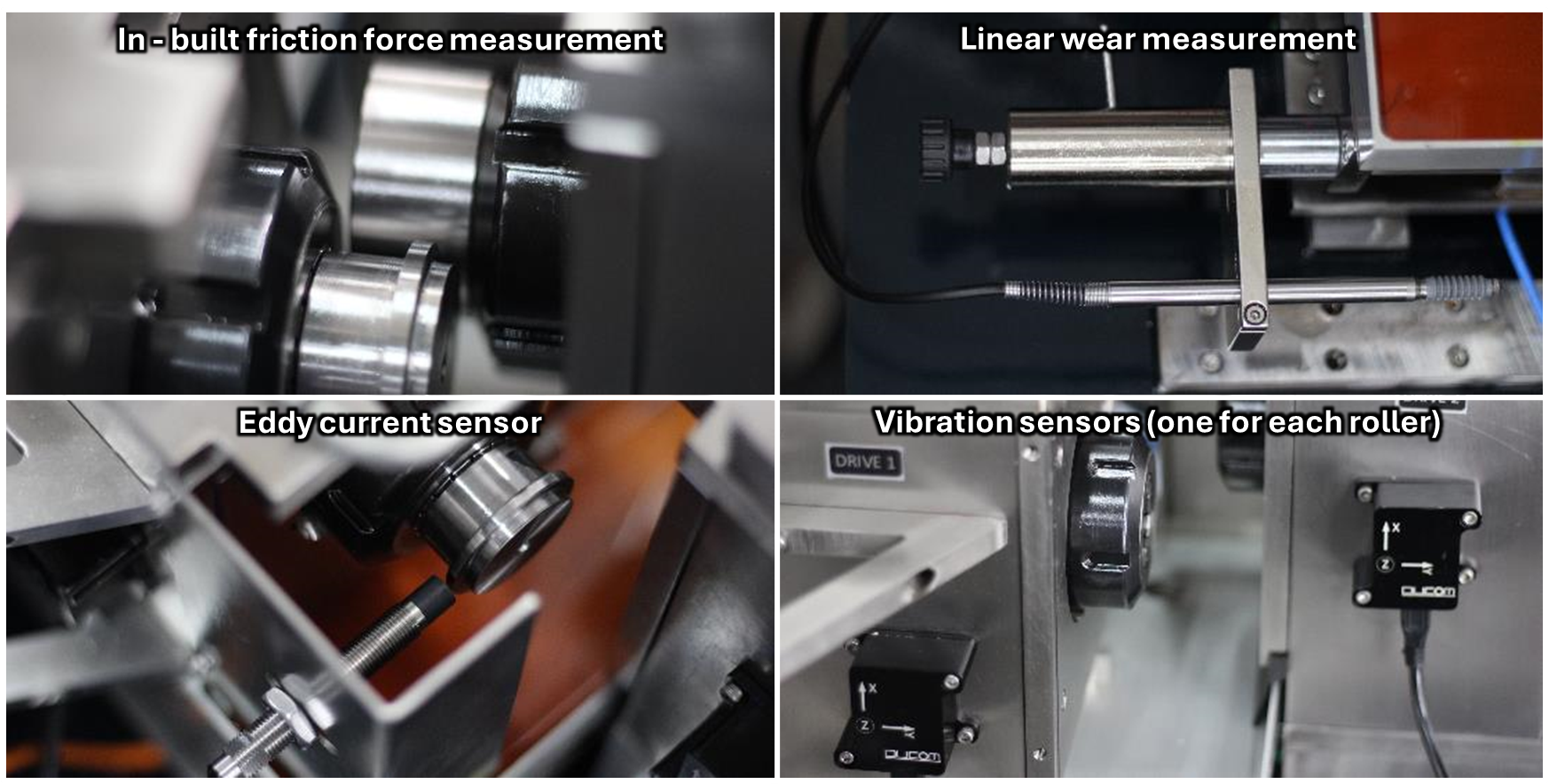

Equipped with friction, wear, and vibration sensors, along with precise controls for load, speed (including slip ratio), and temperature, the Twin Disk tribometer provides a comprehensive suite of data acquisition tools. This array of controls and sensors enables the generation of characteristic curves, mapping lubricants and materials' behavior with changing test parameters. Researchers can accurately correlate variations in the measured quantities to variations in the input parameters, gaining valuable insights into lubricant performance and material durability.

Close-up of the position of the main sensors installed in Ducom Twin Disk.

Conclusion

In conclusion, the investment in a Twin Disk tribometer offers unparalleled advantages for researchers and engineers engaged in tribological studies and lubrication development. From serving as a precursor to FZG testing to providing high-load capabilities, specimen versatility, programmable test profiles, and comprehensive sensor integration, the Twin Disk tribometer empowers researchers to delve deeper into material behaviors and lubrication performance under realistic conditions. By leveraging the capabilities of this advanced testing system, researchers can accelerate innovation, optimize material selections, and advance lubrication technologies for various industrial applications.

These Stories on Twin Disk

USA: +1 (847) 737-1590

India: +91 (80) 4080-5555

Netherlands: +31 (85) 065 74 10