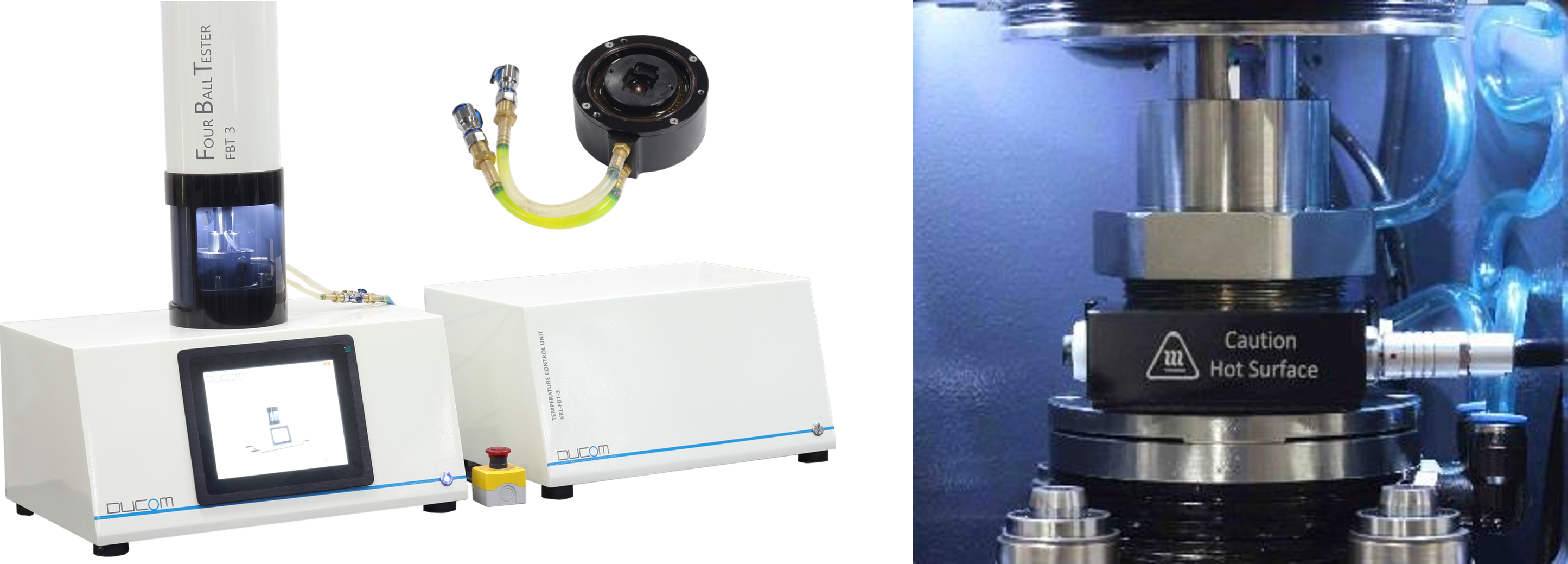

In today's lubricants testing landscape, investing in advanced equipment like the Four Ball Tester (FBT-3) offers significant advantages to research labs. The FBT-3 stands out for its compact, robust design and compliance with rigorous test standards, making it ideal for assessing lubricants' wear preventive, extreme pressure, and frictional properties more efficiently than a simple pin-on-disk setup. With its high level of automation and intuitive interface, the FBT-3 simplifies complex testing processes, enabling users with varying levels of expertise to conduct tests effortlessly. Patented friction measurement technology and automated scar prediction enhance accuracy and convenience in four-ball testing, surpassing traditional methods.

/FBT-3%20full%20image.png?width=859&height=483&name=FBT-3%20full%20image.png)

Ducom tabletop Four Ball Tester (FBT-3) with the complimentary Image Acquisition System.

Essential Design: Maximum Simplicity and Usability

Ducom Four Ball Tester (FBT-3) boasts a minimalist, essential design that translates into maximum simplicity and usability for customers. Its straightforward interface ensures ease of operation, making it accessible even to new technicians, students, and interns. The equipment's short learning curve means users can quickly grasp its functionalities and become productive right away. This design also enhances safety by reducing the risk of operational errors that might arise from complex setups or controls. The point contacts between the four test balls is a self-aligning interface and the results it generates are not subject to variability due to edge loading or imperfect typical of a pin-on-flat configuration, for example.

Assembly of the ball pot before the test.

Touch Screen PC with Standards: Relevance with All FBT Testing Needs

Equipped with a touch screen PC loaded with all relevant test standards and a custom mode, the FBT-3 answers comprehensively to diverse testing requirements. This feature ensures high test throughput for any research lab, allowing for efficient testing across a broad range of technical capabilities. Customers benefit from complete freedom of use of personalized test protocols within its full range, empowering them to conduct tests precisely tailored to their specific needs. Automated test setups (e.g. Stribeck-like curve, user-defined test sequences) enable the development of internal test methods tailored to specific needs. Matching standard results and personalized protocols helps benchmarking of lubricants, as well as a deep understanding of the underlying physical and chemical interactions that occur at the tribopair.

Ducom Four Ball Tester (FBT-3) features pre-loaded test standards for Extreme Pressure (EP) tests and Wear Preventive (WP) tests. The Image Acquisitition System (IAS) (right) allows to quickly measure the wear scar directly from the ball pot.

Automation: Streamlined Testing Processes

The FBT-3 incorporates automated sequences for loading, heating (when applicable), conducting tests, and completing them. This level of automation significantly reduces manual intervention, offering customers an almost fully automated setup. The equipment operates on a "fire and forget" philosophy with built-in safety interlocks, enhancing both efficiency and safety during testing operations. After hitting the Run button, the user can attend to other tasks and trust that the test is carried out precisely and safely (for both personnel and the instrument itself). This multitasking allows for safe operation of the instrument even from non-frequent users such as students or interns, without compromising on the data quality or repeatability.

%20-%20Touch%20Interface.gif?width=584&height=379&name=Four%20Ball%20Tester%20(FBT%203)%20-%20Touch%20Interface.gif)

In just a few clicks a test can be started, for the smoothest user experience in FBT testing.

Modularity: Future-Proof Testing Capabilities

One standout benefit for lubricants researchers is the FBT-3's modularity, which allows for future upgrades when they become necessary of when the budget allows it. With options like a High-Temperature Module (up to 200°C) and a KRL Shear Stability module, users can expand testing possibilities over time, to investigate lubricants beyond the initial scope. This modular approach ensures that laboratories can adapt their testing capabilities as needs evolve or as new budget becomes available, providing a testing platform that is both cost-effective and future-ready.

Ducom FBT-3 can be upgraded with a KRL Shear Stability Tester module (left) and with a High Temperature (200 °C) module (right), even after installation.

Automated Wear Scar Identification and Measurement: Enhanced Post-Test Analysis

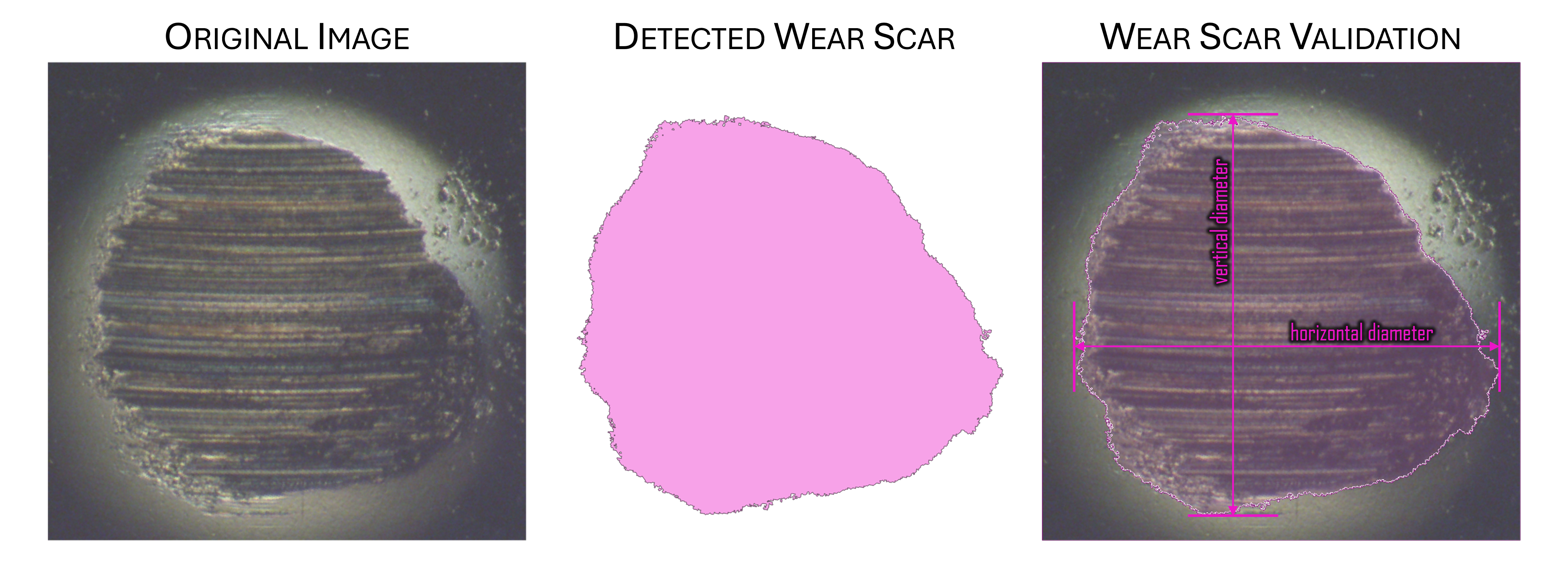

The FBT-3 features an Image Acquisition System that allows to image the tested balls quickly after the test, without removing them from the test holder. Its innovative software includes automated wear scar identification and measurement capabilities, which significantly improve post-test analysis. By automating wear scar diameter edge detection and measurement, operator-specific uncertainty, and number of tests per day is increased. Customers benefit from more accurate and reliable data, leading to informed decision-making based on robust testing outcomes.

Ducom's ownb A.I.-driven software can analyze an uploaded wear scar image to detect the edges of the wear and measure the mean wear scar diameter (MWSD) automatically.

Conclusion

In conclusion, the investment in a Four Ball Tester like the FBT-3 represents a strategic move for companies and universities aiming to optimize lubricants testing. Its advanced features, including touchscreen interface, patented measurement technology, and automatic scar prediction powered by Artificial Intelligence, streamline testing workflows and deliver precise, reliable results. The FBT-3's adaptability to diverse testing needs and its capability to handle demanding applications ensure enhanced productivity and quality in lubricant evaluation. By embracing modern testing technologies like the FBT-3, organizations can stay ahead in lubricants research and development, ultimately driving innovation and efficiency in their operations.

These Stories on Ball Wear

USA: +1 (847) 737-1590

India: +91 (80) 4080-5555

Netherlands: +31 (85) 065 74 10