Four Ball Tester (FBT) was first introduced in 1933 by Gerrit Daniel Boerlage for the purpose of studying the behavior of lubricants under extreme pressure. As its name suggests, the tribometer is built around four steel balls, that are the specimens used for testing the lubricants.

Principle of Operation

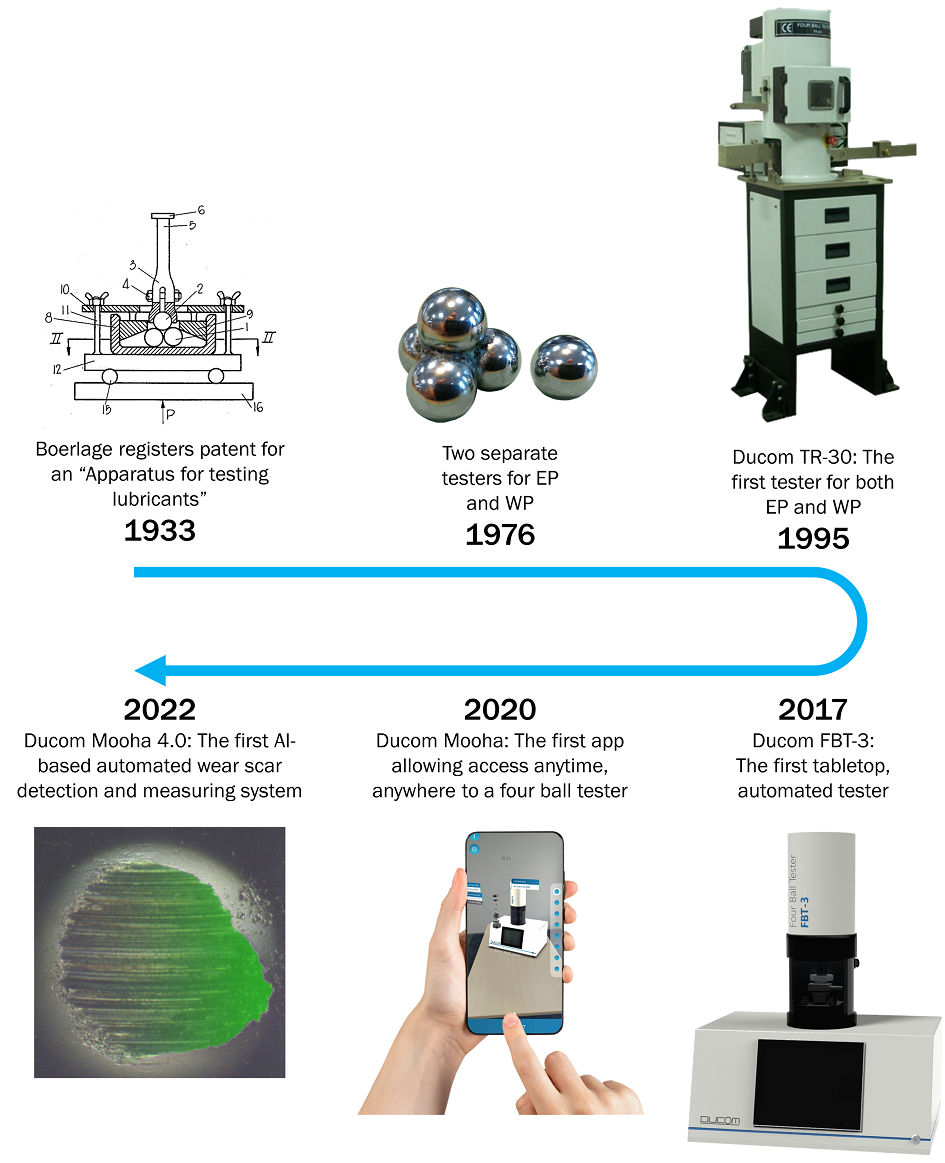

Since its invention almost 90 years ago, the basic design and principle of operation have not changed. Three balls are clamped inside a lubricant cup, filled with the lubricant under investigation (Figure 1). The fourth ball is clamped in a holder (chuck or collet), loaded against the bottom balls and rotated at high speed, according under prescribed test protocols (ASTM/DIN/ISO). Wear scar, friction and scuffing loads are reported.

Figure 1. Drawing from the original 4-ball tester patent (1934)

Evolution of the Four Ball Tester

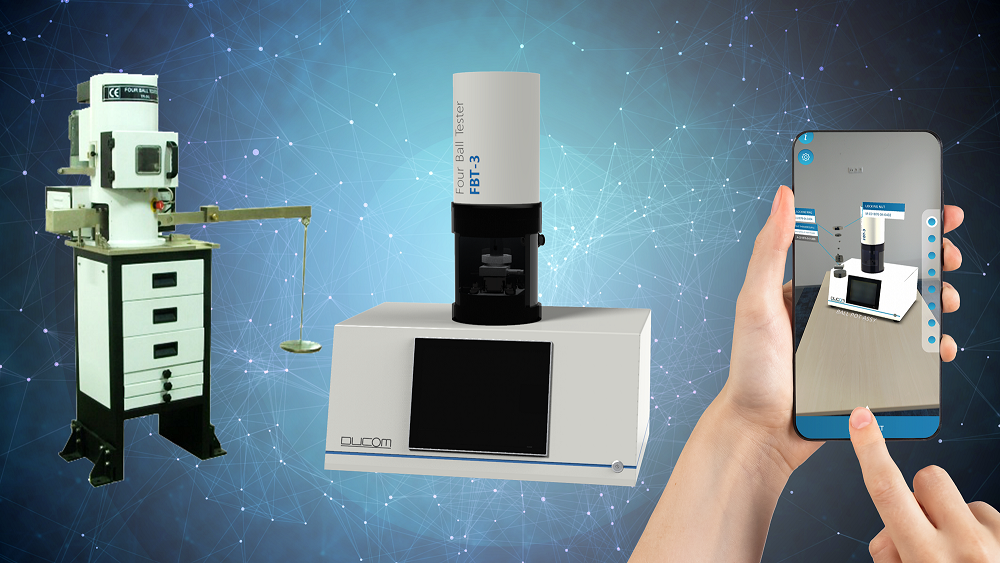

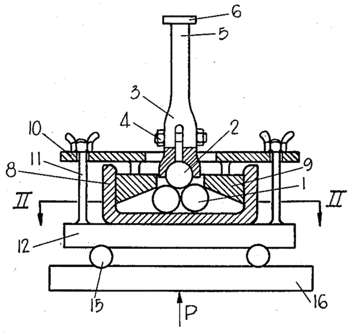

Figure 2. Timelines of 4-ball tester development and innovation

Figure 2. Timelines of 4-ball tester development and innovation

Although the core design and working principle remains unchanged till date, many characteristics of a Four Ball Tester have evolved from the first rudimentary prototype, to more advanced core with superior sensors. Ducom has been at the forefront of technology breakthroughs over the past 30 years (Figure 2) spearheading major disruptions such as the first 4-ball tester for both WP and EP tests in 1995, the first compact, tabletop, automated 4-ball (FBT-3) in 2017 with patented friction measurement, the first app-based digital anytime, anywhere access MOOHA in 2020 to the first artificial intelligence, A.I.-based wear scar measurement in 2022.

Common Platform for WP and EP TestsEarly 4-ball testers in the 1970's were only capable of running either WP or EP tests, a lab needed two separate instruments due significant load and torque differences . Ducom Instruments was the first company to break that barrier in the 1990's to manufacture a single 4-ball tester compliant with both EP and WP tests (100 to 10,000 N) with a load stability ± 2 N across the range This offered a significant value proposition to the lubricant labs.

Automation

The next development pushed this envelope further with a radical design, the 1st automated, compact 4-ball FBT-3, with preloaded protocols. This eliminated several manual steps in the workflow, potential errors in setting up tests and enhanced lab productivity. Automated loading made operation effortless and safe for women scientists and created a gender-neutral instrument (Figure 3) while still complying with with global test standards. (Read the full article here - Women Scientists in Lubricant Industry). Other manufacturers have imitated Ducom and developed their versions of table-top automated 4-ball tester, but FBT-3 remains the Real McCoy in terms of technology and adoption by the leading lubricant labs.

Figure 3. Women Scientists in Lubricant Industry, clockwise from top left, Victoria Granja (Rice Univ.), Eva Ortega (Brugarolas), Deepti Bapat (Shell), Angela Tortora (Ducom)

Accurate Friction Measurement

In the early days, friction was measured by means of a pivoted arm with a counterweight and a pointer connected to a pen, that would draw a friction graph on a rotating drum (Figure 4A). Today, force sensors are commonly used . The challenge that many instrument manufacturer's face with friction measurement is the range - values of CoF that can be as low as 0.03 at loads of 100 N to as high as 0.25 at loads of 10000 N.

Figure 4A. Friction measurement in the original 1934 four ball tester Figure 4B. Friction torque measurement in Ducom 4-ball Tester (FBT-3)

Figure 4A. Friction measurement in the original 1934 four ball tester Figure 4B. Friction torque measurement in Ducom 4-ball Tester (FBT-3)

Ducom 4-Ball Tester (FBT-3) features a patented friction measuring system (Figure 4B) with frictionless support module that offers accurate lubricant friction at the extremes, i.e., CoF as low as 0.03 (ASTM D5183 friction test) to CoF as high as 0.5 (ASTM D2783 weld load test). This has helped scientists differentiate lubricants that exhibit similar scuffing characteristics.

Wear Scar Imaging

Measuring the mean wear scar diameter (MWSD) on the balls has always been challenging and error-prone; starting with locating scars on the ball (sometimes as small as 200 µm) followed by manually orienting each scar perpendicular to the optical axis of a standard metallurgical microscope (Video 5).

Video 5. Traditional ball wear measurement vs. Ducom Image Acquisition System for in situ measurement of ball wear scar

Video 5. Traditional ball wear measurement vs. Ducom Image Acquisition System for in situ measurement of ball wear scar

The Image Acquisition System (IAS) was developed for in-situ wear scar imaging of all three lower balls in the native state within the ball pot.

Mooha A.I. based automated wear scar measurement. In many cases, wear scars present challenges in detecting edges due to jagged boundaries, delamination and/or material transfer which can mislead manual measurements and result in significant variability (Figure 6). Mooha with Artificial Intelligence (A.I.) algorithm was developed to identify the wear scar edges and automatically quantify wear. During processing, a mask is placed around the edges and X-Y axes drawn for estimating mean wear scar diameter. (Read the full article here - Automation in Wear Scar Measurements).

Figure 6. Uneven wear scars, delamination, material transfer and Mooha A.I. enabled automated wear edge definition

The open-access cloud-based software enables anytime, anywhere measurement capability. It overcomes human error and reduces the test variability.

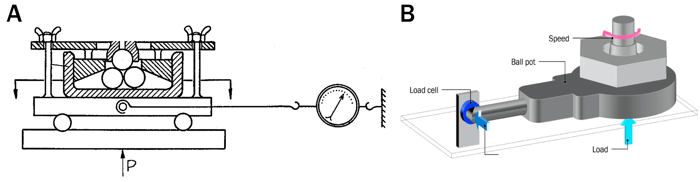

Mooha: Digital Tribolab Assistant for the Modern Lubricant Lab

Mooha is a Ducom proprietary software that leverages Industry 4.0 technologies to allow anytime, anywhere access to FBT-3. Users can monitor instrument health, access live data during the test and use inbuilt industry standard statistical tools for comparing big data sets and generating detailed reports within a few clicks. The data storage follows ISO 27001 guidelines, cannot be manipulated and offers complete traceability. A phone based app (Figure 7) offers 3D visualization of FBT-3 with virtual digital twin that substitutes as a quick training guide in a user's palm.

Figure 7. Mooha based training, operation and data analysis using the smart phone App-based platform.

Summary

Ducom has reinvented 4-ball tester into a state-of-art test platform with several breakthroughs over the past 30 years. Good correlation with legacy datasets have been validated in benchmarking tests across R&D and Quality Control labs within the lubricant industry. Automation has simplied standard workflows, an intuitive digital interface has eliminated complex data processing and analysis. Mooha enabled 3D training has simplified learning and instrument operation. From a manufacturer's perspective, FBT-3 has several embedded features that will ensure it stays ahead of the curve ready for changes in the test protocols (KRL shear stability module) and challenges in new lubricant requirements (200 deg C test module). From a scientist's perspective, FBT-3 with Mooha offers reliable data in a rapid manner for different formulations, thereby making more time and energy available to focus on what matters - scientific ingenuity for developing sustainable lubricant solutions.

These Stories on friction

USA: +1 (847) 737-1590

India: +91 (80) 4080-5555

Netherlands: +31 (85) 065 74 10