Brake-dynamometer is an expensive and time consuming technique for quality control or selection of brake materials. Brake-dynamometer is a technique used for performance evaluation of the braking device under the realistic vehicle speed, mass and inertia. The price of a brake-dynamometer is estimated to be greater than € 250.000. However, such an expensive technique is only limited for testing the braking device. Moreover, the brake materials has to be shaped into a component to make the braking device that fit into the brake-dynamometer.

The best solution is to use the pin-on-disk or rotary tribometer for friction and wear testing of the brake materials. Although this test method will not reproduce the vehicle mass and inertia but it can reproduce the vehicle driving speed pattern- acceleration, cruise, deceleration and the high temperature (up to 600°C) in the braking device. Ducom Multi Capability Tribometer (see Figure 1) is cheaper than brake-dynamometer moreover it offers the ease of testing and high throughput research focused on selection of brake-material.

/Videos%20and%20Images/Ducom%20POD%204.0%20-%20Screen%20Grab.png?width=669&name=Ducom%20POD%204.0%20-%20Screen%20Grab.png) Figure 1. Ducom Multi Capability Tribometer POD 4.0

Figure 1. Ducom Multi Capability Tribometer POD 4.0

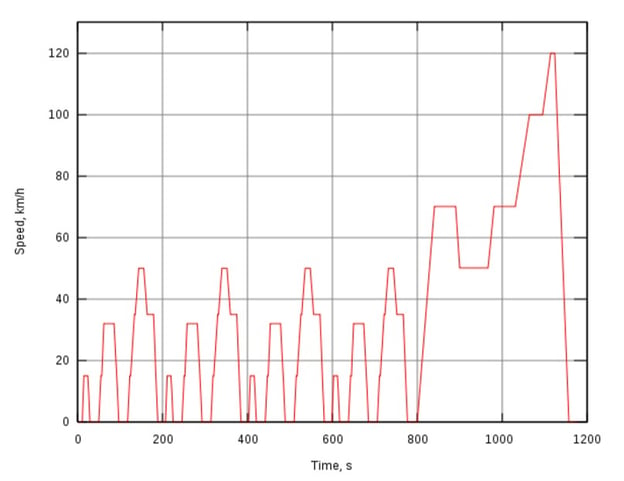

In this study, the test speed is varied according to the vehicle driving pattern or European urban driving cycle - UDC (see Figure 2).

Figure 2. Speed profile (UDC). Each cycle is comprised of acceleration, cruise, deceleration.

Figure 2. Speed profile (UDC). Each cycle is comprised of acceleration, cruise, deceleration.

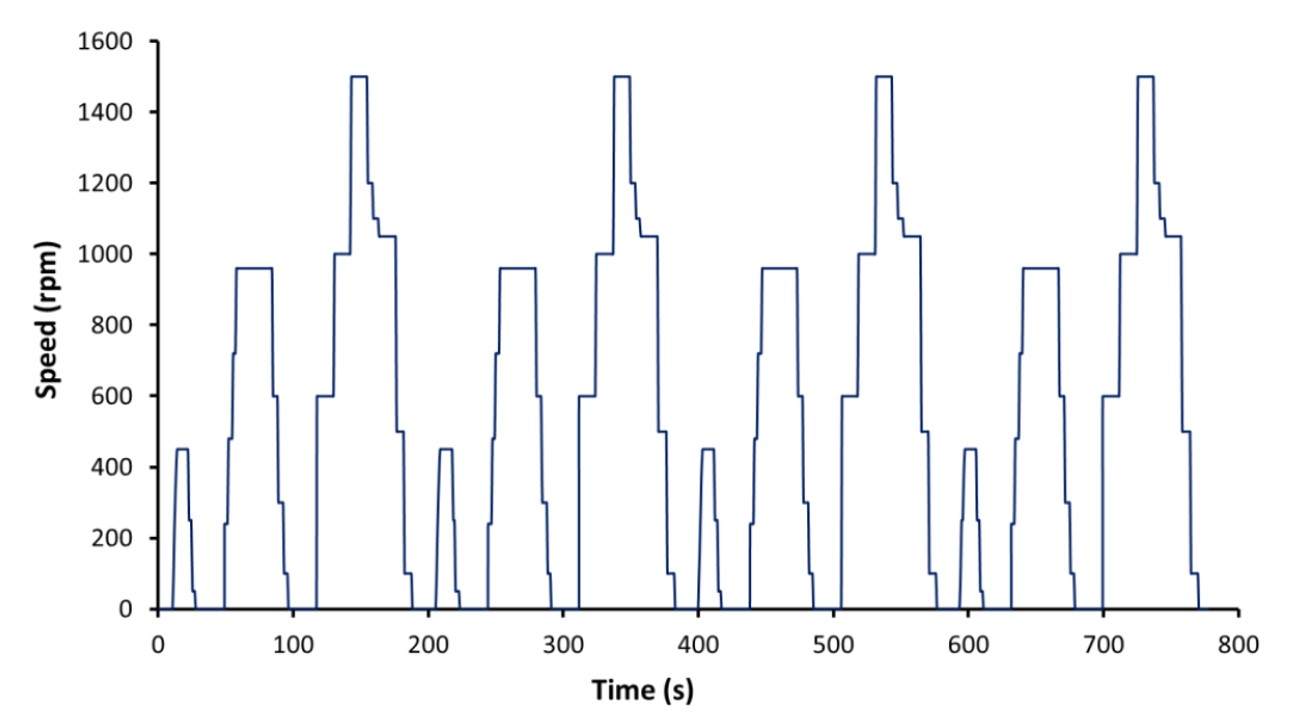

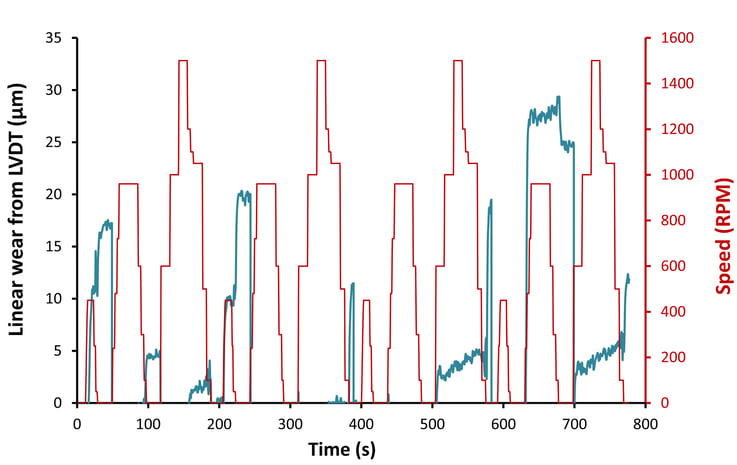

Figure 3 shows the UDC speed profile reproduced using Ducom Multi Capability Tribometer POD 4.0.

Figure 3. Speed profile in Ducom POD 4.0

Figure 3. Speed profile in Ducom POD 4.0

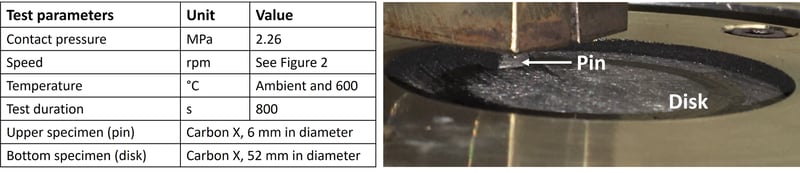

Table 1 summarizes the test parameters and materials used in this study. Labview based WinDucom software was used to control the pin temperature, acquire the friction force and linear wear during the test.

Table1. Test parameters and materials.

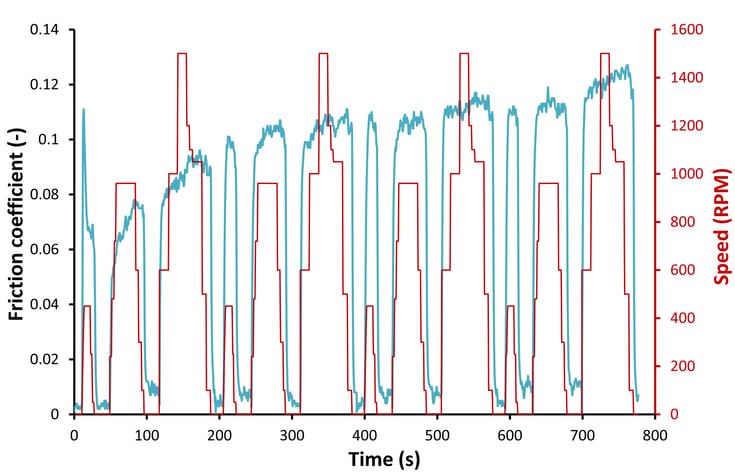

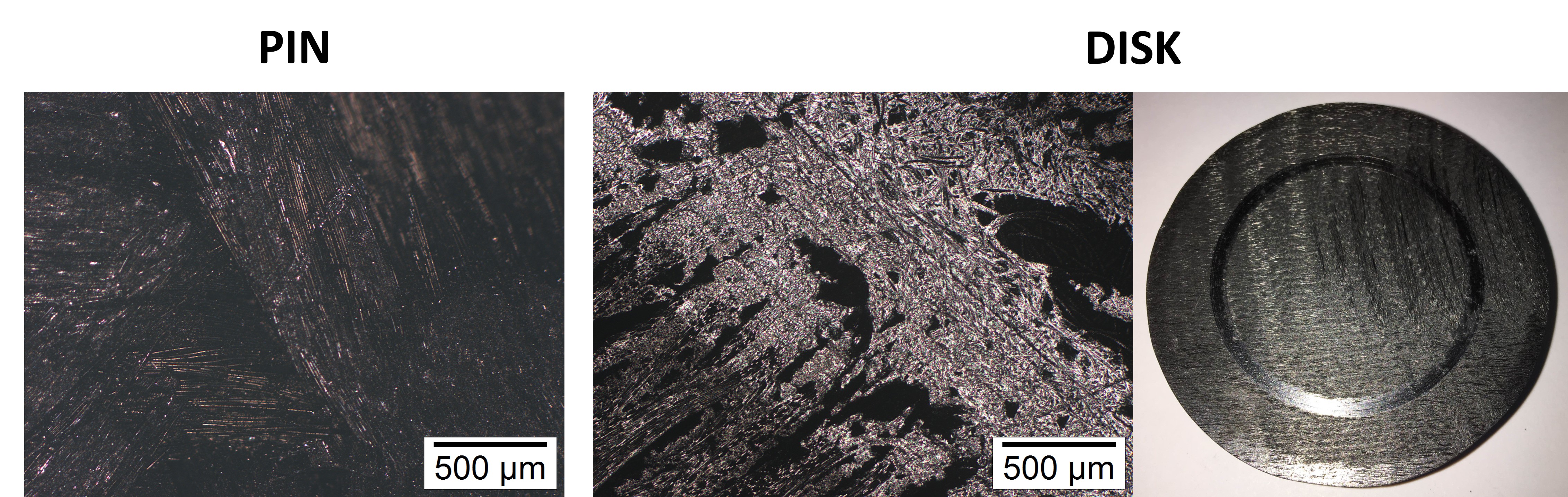

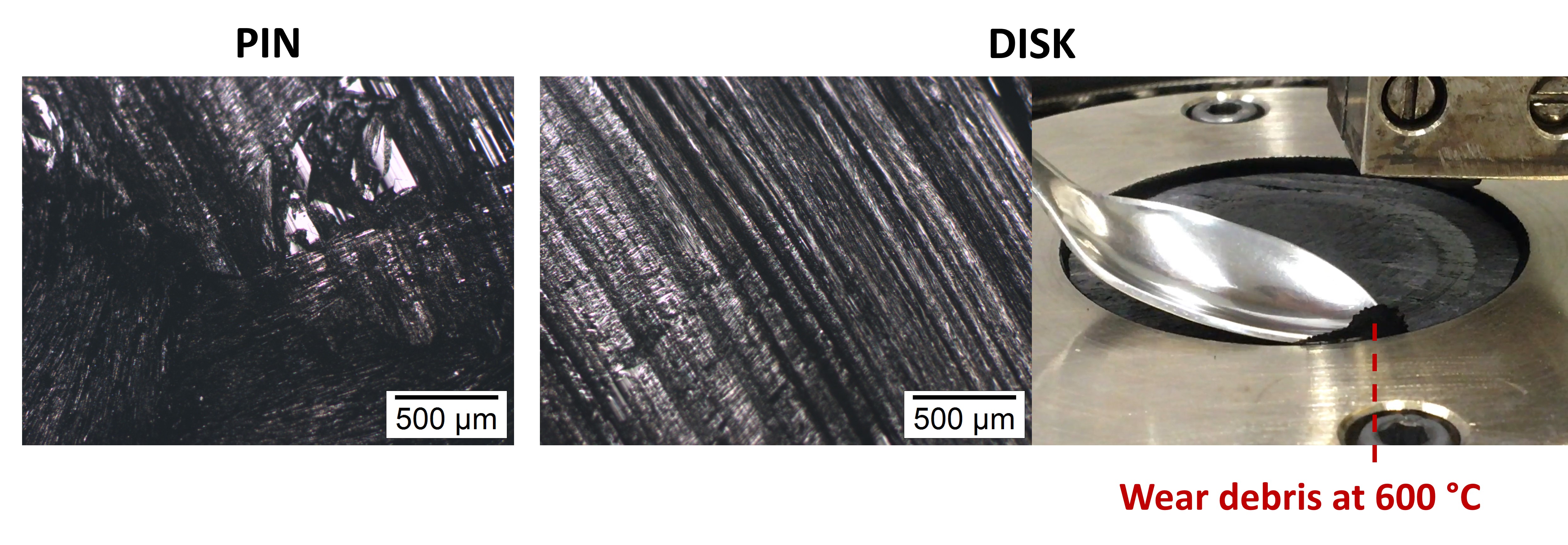

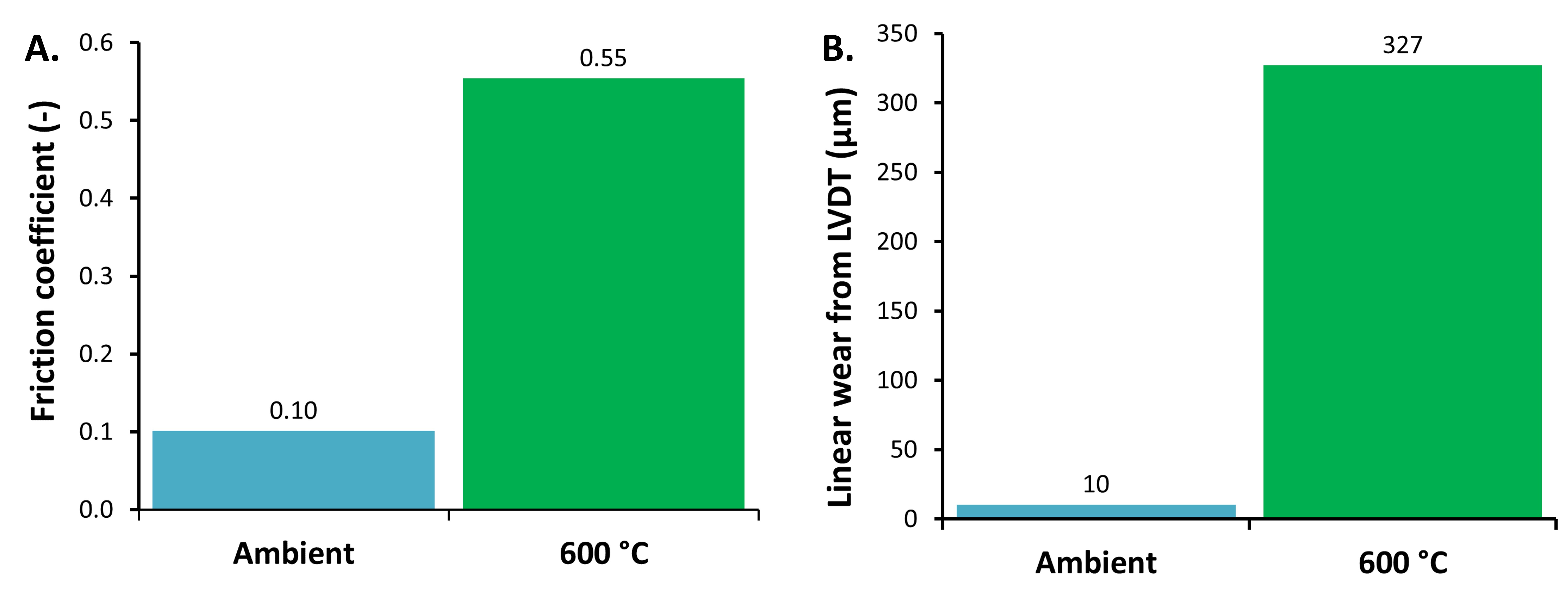

Test Results | Ambient Temperature

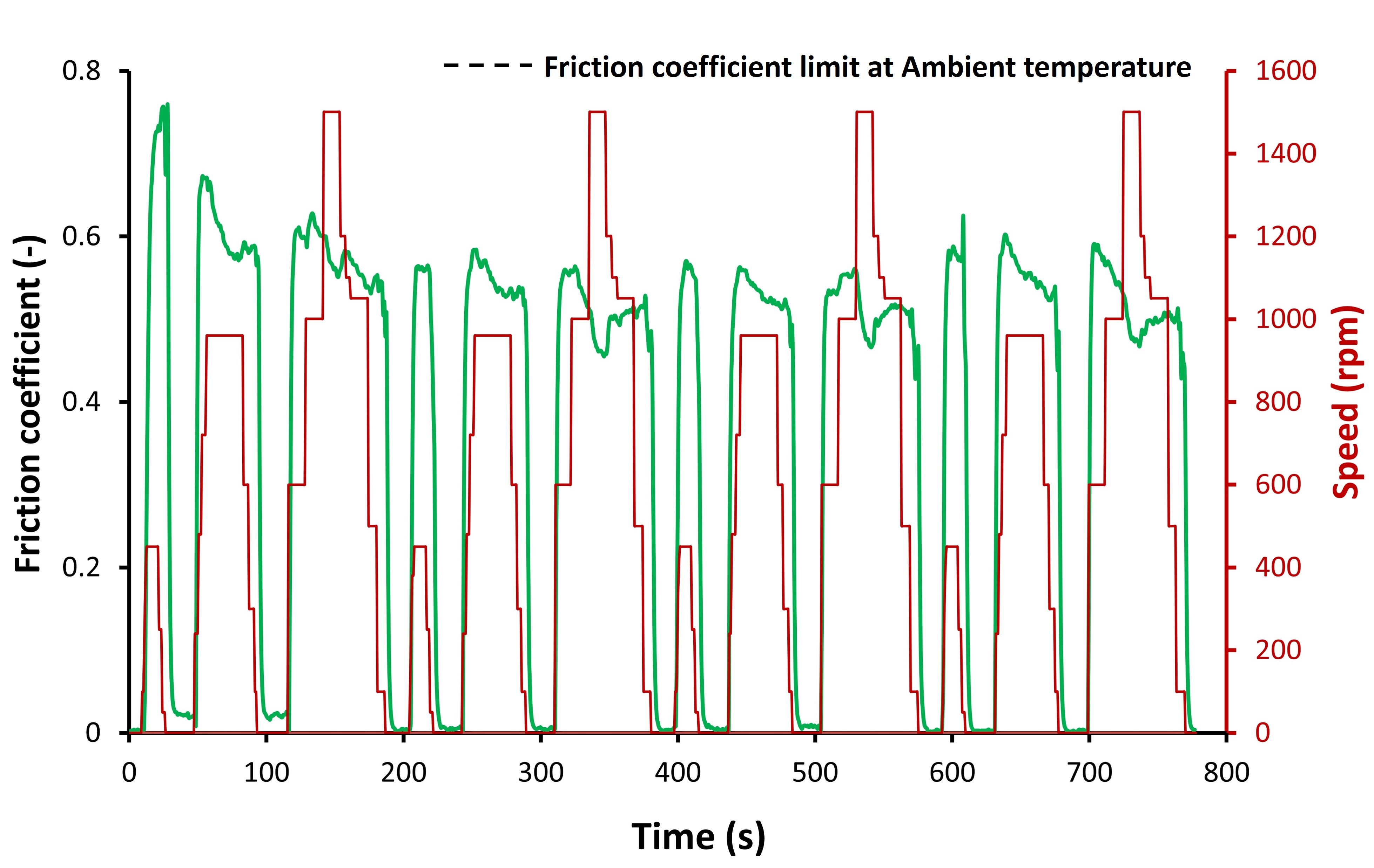

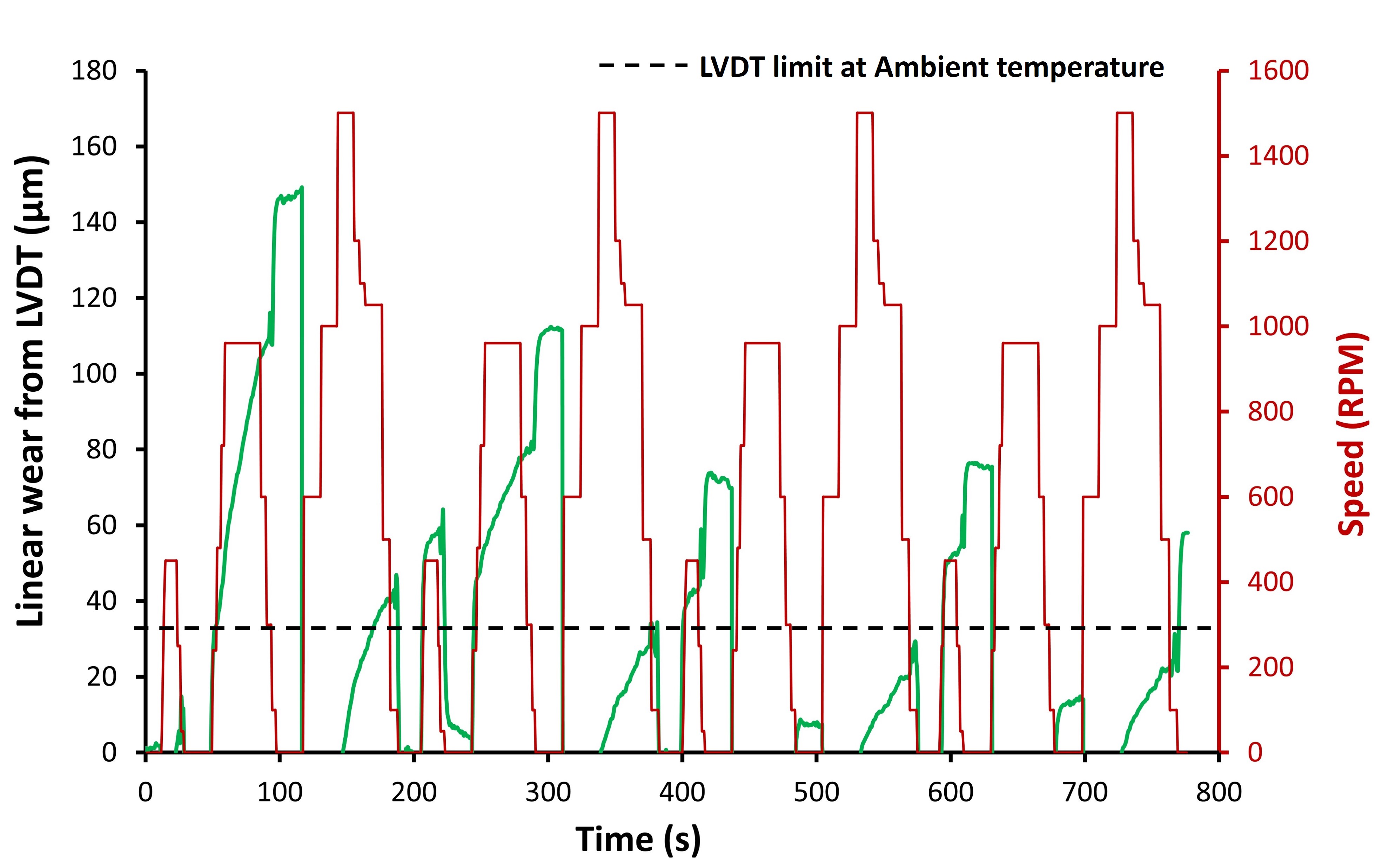

Test Results | 600 °C

Test Results | During Deceleration

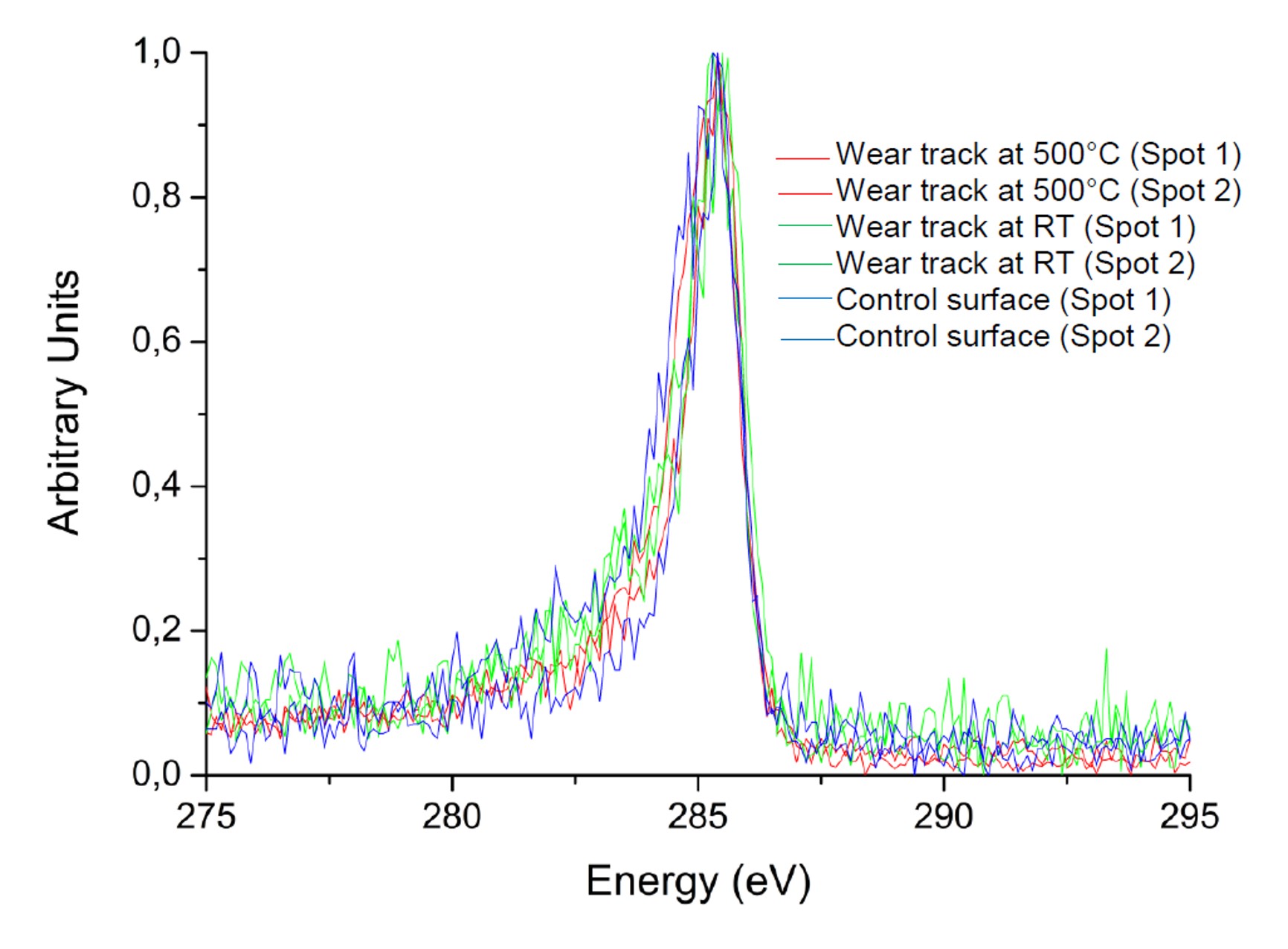

Test Results | Carbon Peak Analysis (XPS)

These Stories on high temperature

USA: +1 (847) 737-1590

India: +91 (80) 4080-5555

Netherlands: +31 (85) 065 74 10