Sensory perception of the milk food products is influenced by its fat content. Creaminess perception is known to increase with the fat content and it could be related to the lubrication between the oral surfaces. Therefore, we investigate the lubrication by low and high fat milk at the soft hydrophobic surfaces.

MATERIALS AND METHODS

MILK SAMPLES. Low-fat cow milk (0.3% fat) and high-fat milk (3.5% fat) were commercial products purchased from the local supermarket. These samples were from the same manufacturer or supplier. Note that the protein contents were the same for the low- and the high-fat milk. Demineralized water was used as control in all the experiments.

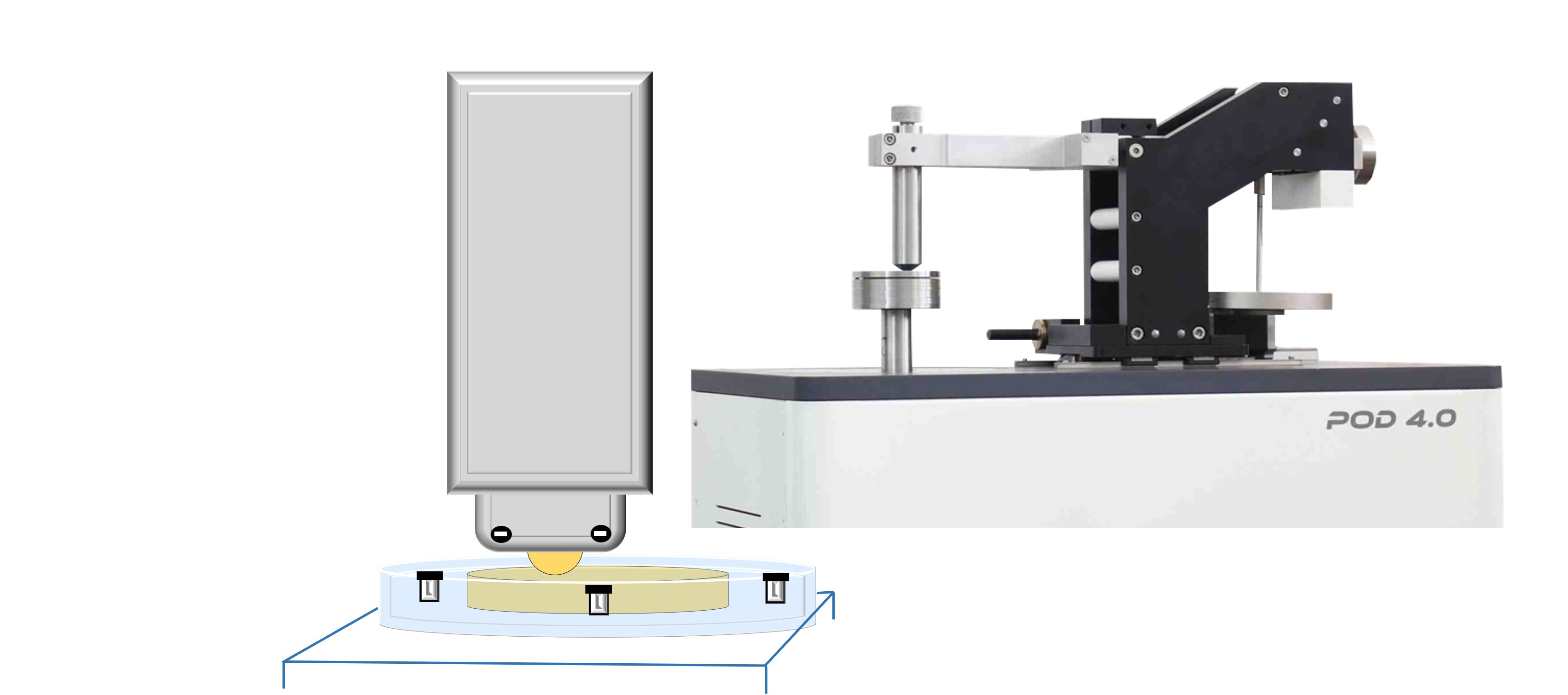

TEST SPECIMENS. Polydimethylsiloxane (PDMS) pins and disks were used in friction measurements (see Figure 1). They were prepared from a silicon elastomer kit (Sylgard 184, Dow corning, Midland, MI). The base and the curing agent were mixed in a ratio (w/w) of 10:1 and transferred into the molds of pins and disks. Overnight curing was conducted at 65°C in an oven. A mold with polystyrene hemispherical wells was used to prepare a hemispherical pin of 6 mm diameter and a polystyrene circular plate was used to prepare a disk of 60 mm diameter. The roughness of the PDMS disks and pins was measured by contact-mode atomic force microscopy. The average roughness was measured to be 3 and 5 nm for the disks and pins, respectively.

Figure 1. PDMS pin and disk mounted on a pin on disk instrument.

Figure 1. PDMS pin and disk mounted on a pin on disk instrument.

FRICTION COEFFICIENT MEASUREMENTS. Friction coefficient (μ) was determined using a pin on disk instrument, Ducom Multi Capability Tribometer - POD 4.0 (see Figure 2). This instrument can operate under a normal load range of 1 – 200 N and a speed range of 1–3000 rpm.

/Videos%20and%20Images/Applications%20and%20Blogs/POD%204.0/POD%204.1_schematic.jpg?width=2000&name=POD%204.1_schematic.jpg) Figure 2. Ducom Multi Capability Tribometer (POD 4.0) with rotary and linear modules.

Figure 2. Ducom Multi Capability Tribometer (POD 4.0) with rotary and linear modules.

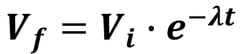

Winducom software was used to determine the friction coefficient as the disk sliding velocity was continuously decreased with time from 80 to 2 mm/s at an exponential rate as follows:

where

where

Vf and Vi are the initial and final velocity (mm/s), respectively

the constant λ represents the velocity decay rate

t represents the duration in seconds

The velocity decay rate was fixed at 0.003 for three loading conditions, that is, 1.5, 6.5, and 11.5 N. In another set of experiments, the load was fixed at 1.5 N for three different decay rate conditions, that is, 0.003, 0.005, and 0.009. In this study we report the results of the Stribeck Curves generated at decay rate of 0.003 (see Figure 3). The full test results are available in the published manuscript "Load- and Velocity- Dependent Friction Behavior of Cow Milk Fat".

Figure 3. Exponential decay of disk sliding velocity as a function of time. The decay rate (λ) is 0.003.

Figure 3. Exponential decay of disk sliding velocity as a function of time. The decay rate (λ) is 0.003.

Note that as λ is increased, the velocity sweep is quicker, which can influence the rate of recovery of perturbed surface layers. In all the experiments, the total volume of milk and demineralized water (control) was 4 mL. Note that demineralized water is deionized water without any minerals.

TEST RESULTS

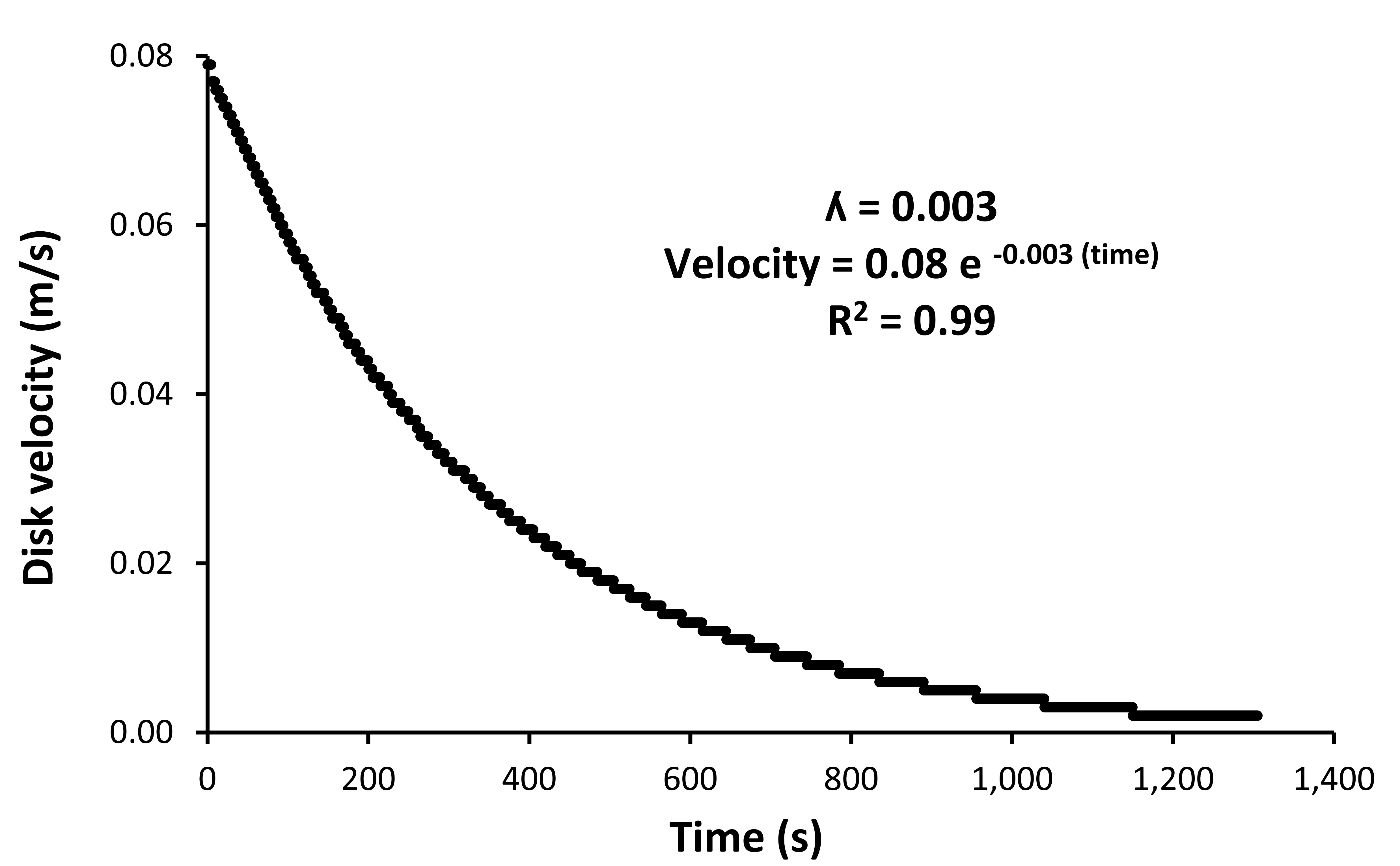

At 11.5 N load, the friction coefficient trend for the 0.3 % and 3.5 % fat milk samples was similar (see Figure 4C).

Figure 4. Stribeck curves for milk and water. Change in the friction coefficient (μ) as a function of disk velocity for 3.5 % fat milk, 0.3 % fat milk and control (water) at the normal load of 1.5 N (A), 6.5 N (B) and 11.5 N (C). Data presented include two repetitions per load. The velocity decay rate (λ) was fixed at 0.003.

Figure 4. Stribeck curves for milk and water. Change in the friction coefficient (μ) as a function of disk velocity for 3.5 % fat milk, 0.3 % fat milk and control (water) at the normal load of 1.5 N (A), 6.5 N (B) and 11.5 N (C). Data presented include two repetitions per load. The velocity decay rate (λ) was fixed at 0.003.

Friction coefficient decreases with an increase in the load for demi water whereas the friction coefficient remains stable for 0.3 % fat milk (see Figure 5).

Figure 5. Relationship between the friction coefficient and normal load for 3.5 % fat milk, 0.3 % fat milk and control (water). Data presented include two repetitions per load.

Figure 5. Relationship between the friction coefficient and normal load for 3.5 % fat milk, 0.3 % fat milk and control (water). Data presented include two repetitions per load.

CONCLUSIONS

Moreover, hydrophilic tails are useful in quick replenishment of water molecules that sustain low friction compared to the fat molecules on surface.

Figure 6. Schematic of surface layer composed of casein and fat molecules, adsorbed on PDMS surfaces after shear thinning, for 0.3 % fat milk (A) and 3.5 % fat milk (B).

Figure 6. Schematic of surface layer composed of casein and fat molecules, adsorbed on PDMS surfaces after shear thinning, for 0.3 % fat milk (A) and 3.5 % fat milk (B).

The full test results are available in the published manuscript "Load- and Velocity- Dependent Friction Behavior of Cow Milk Fat".

These Stories on Stribeck Curve

USA: +1 (847) 737-1590

India: +91 (80) 4080-5555

Netherlands: +31 (85) 065 74 10