Introduction

Diesel as a fuel in internal combustion engine should also lubricate the moving parts like gear box in fuel pump. Quality of diesel related to its lubricity is determined using the high frequency reciprocating rig (HFRR), it is a wear test method that was developed by Infineum and Imperial College in London. The design, test method and results from HFRR are well described in standards like ASTM D6079 and ISO 12156. HFRR is a powerful tool in lubrication, as it is become a key enabler of pollution control.

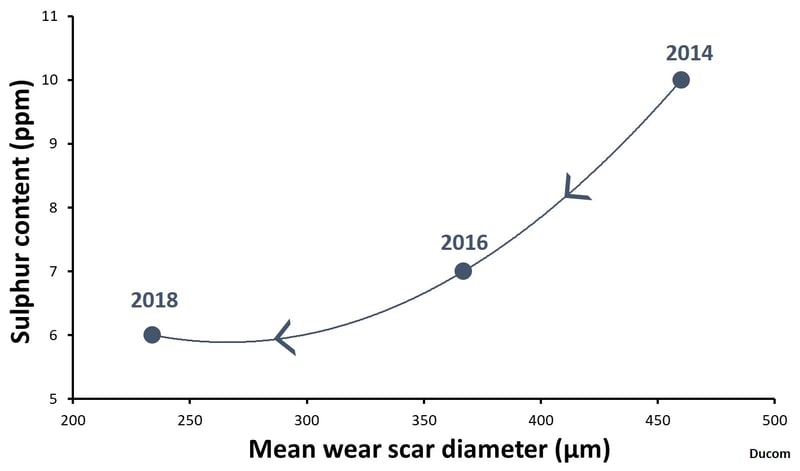

HFRR test method is recognized by several regulatory bodies that control the quality of diesel and its emission of pollutants. EN 590 from European Union (EU) prescribes the limits to physical properties of diesel fuel sold in EU. For example, there are limits to sulphur content in diesel, that is aimed at complete desulphurization of diesel without affecting its lubricity behavior (see Figure 1). This will allow combustion engines to work cleaner, reduce NOx /CO/HC and particulate matters (PM).

Note: Sulphur reacts with steel to form Iron sulphide layer that acts as a lubricant. Desulphurization is not good for diesel lubricity. Therefore, alternative lubricious molecules are added to low sulphur diesel, few examples are boron-based compounds that can form lubricious boric acid and biodiesel.

The objective of this study is to assess the lubricity of diesel fuel from different gas stations in Groningen (Netherlands). These gas stations were randomly selected, and we use Ducom HFRR to verify their compliance with EN 590.

Figure 1. EN 590 prescribed Sulphur content (ppm) and mean wear scar diameter (um) in 2014, 2016 and 2018 (EU Emission VI).

Materials and Methods

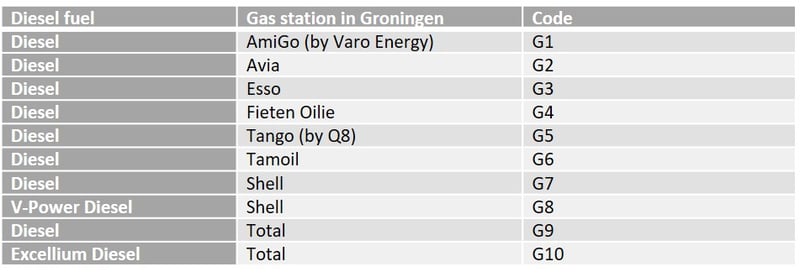

Diesel fuel: The diesel fuel samples were procured from different gas stations in the city of Groningen, The Netherlands (see Table 1). Diesel fuel samples were taken during the second transition period according to the Cold Filter Plugging Point (CFPP) specifications in the Netherlands 1st March to 14th April).

Table 1. Diesel fuel from gas station Total, Shell, Tamoil, Esso, Avia, AmiGo, Fieten Oilie and Tango (Q8) in Groningen, The Netherlands. The section “code” is specific to this study.

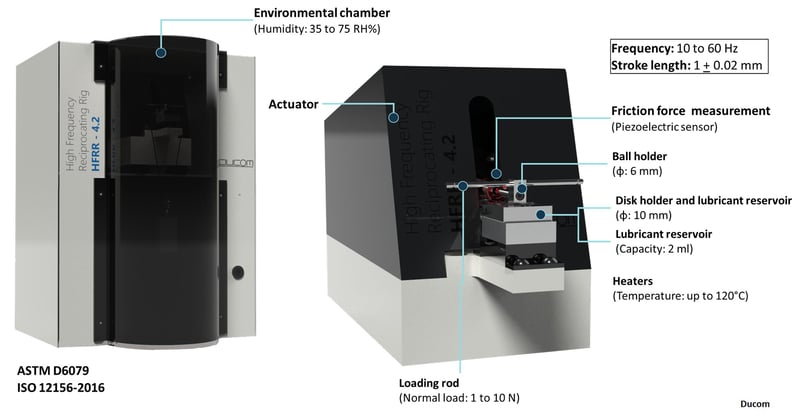

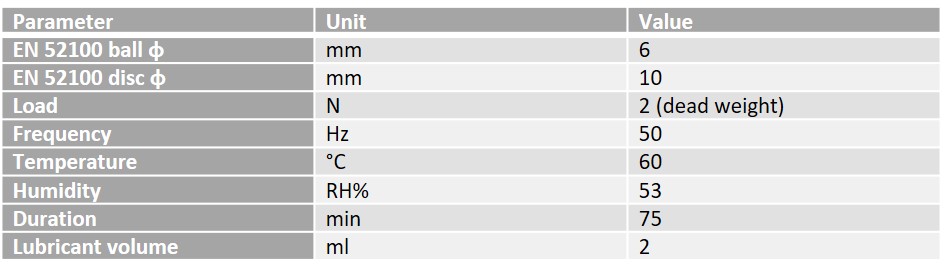

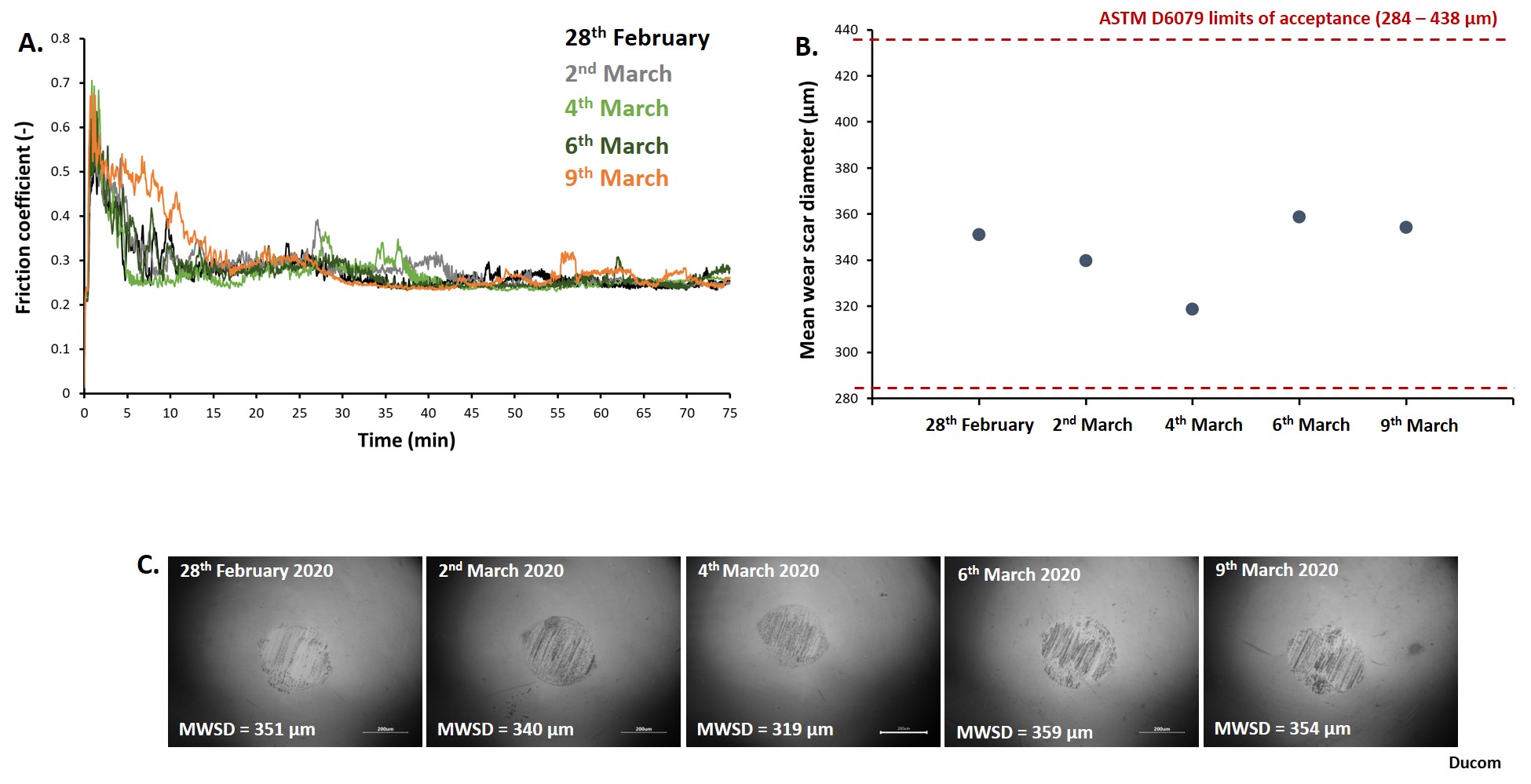

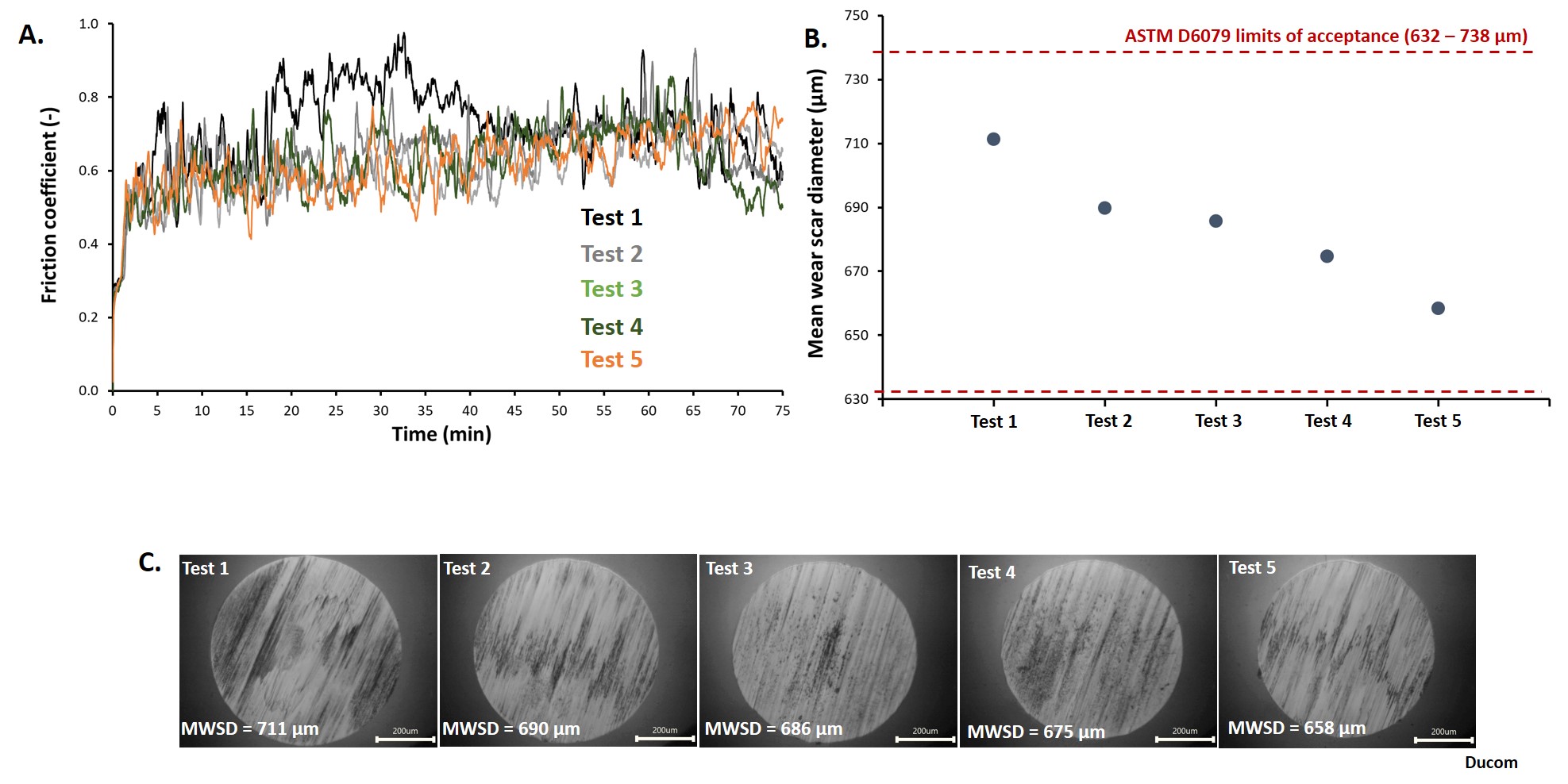

HFRR Lubricity: High Frequency Reciprocating Rig or HFRR 4.2 (see Figure 2) manufactured by Ducom Instruments (Netherlands) was used in this study. Ducom HFRR is a ball on disk type tribometer with linear reciprocation engine (or vibrator), friction piezo-sensor and temperature control unit, that works in compliance with ASTM D6079 (refer to Table 2). The ball mean wear scar diameter (MWSD) is determined according to ASTM D6079 and it is used as a key metric for comparing the lubricity behavior of different diesel fuel. As our standard protocol, the Ducom HFRR was validated using Reference Fluid A and Reference Fluid B before testing the diesel fuel. The mean wear scar diameter values were within the lower and higher acceptance limit set by the ASTM D6079 in all cases (see Figure S1 and S2 in the supplementary material).

All the tests were conducted in triplicates to verify repeatability and for statistical analysis.  Figure 2. Description of the Ducom High Frequency Reciprocating Rig (HFRR 4.2) used in this study.

Figure 2. Description of the Ducom High Frequency Reciprocating Rig (HFRR 4.2) used in this study.

Table 2. Diesel fuel lubricity test parameters according to ASTM D6079, using Ducom HFRR.

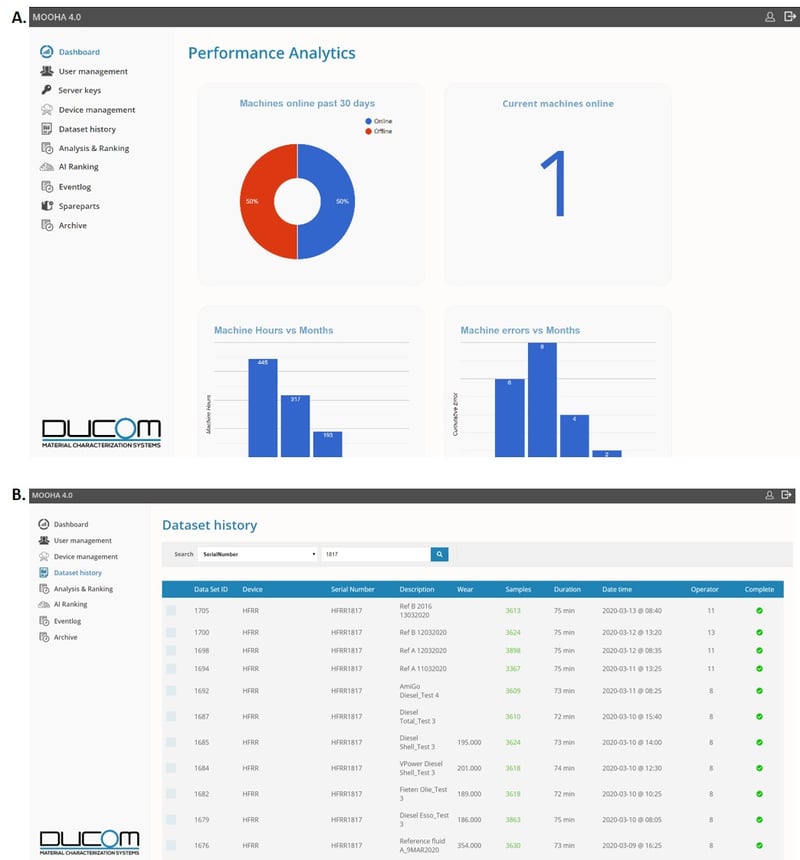

Mooha: HFRR embedded with automation software like Mooha helped us to continuously monitor the data quality and instrument health, by using mobile or desktop platform. All the data sets from this study were captured, labelled and stored safely in the cloud (or in our organization server) without any intervention by the operator. In couple of seconds, the statistical analysis of all big data from HFRR was reported. Mooha, is also an automated lab information system, that has helped us in data traceability, test comparison, statistical graphs and report generation, used in this study.

Mooha is a product developed by Ducom Digital

Figure 3. Mooha dashboard interface for (A) performance analytics of the lab and (B) dataset history of all the tests performed in the lab. The data can be visualized searching for the serial number of the instrument, operator ID or test description. More options are also available: User management, device management, analysis and ranking, AI ranking, event log and archive.

Results

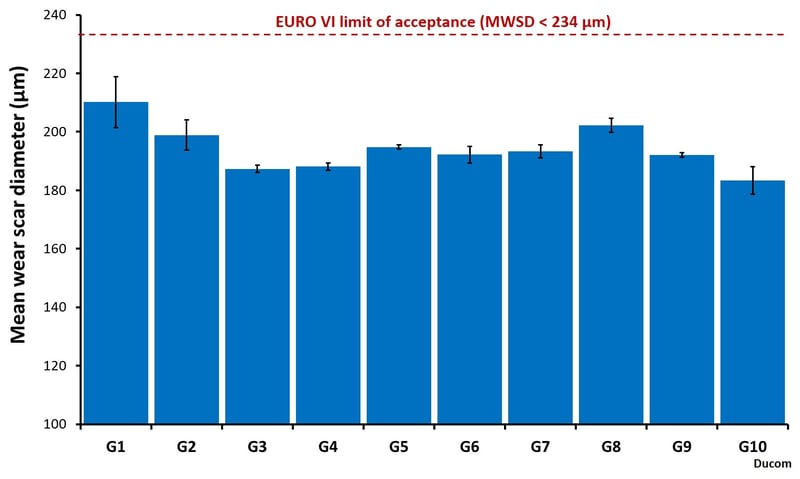

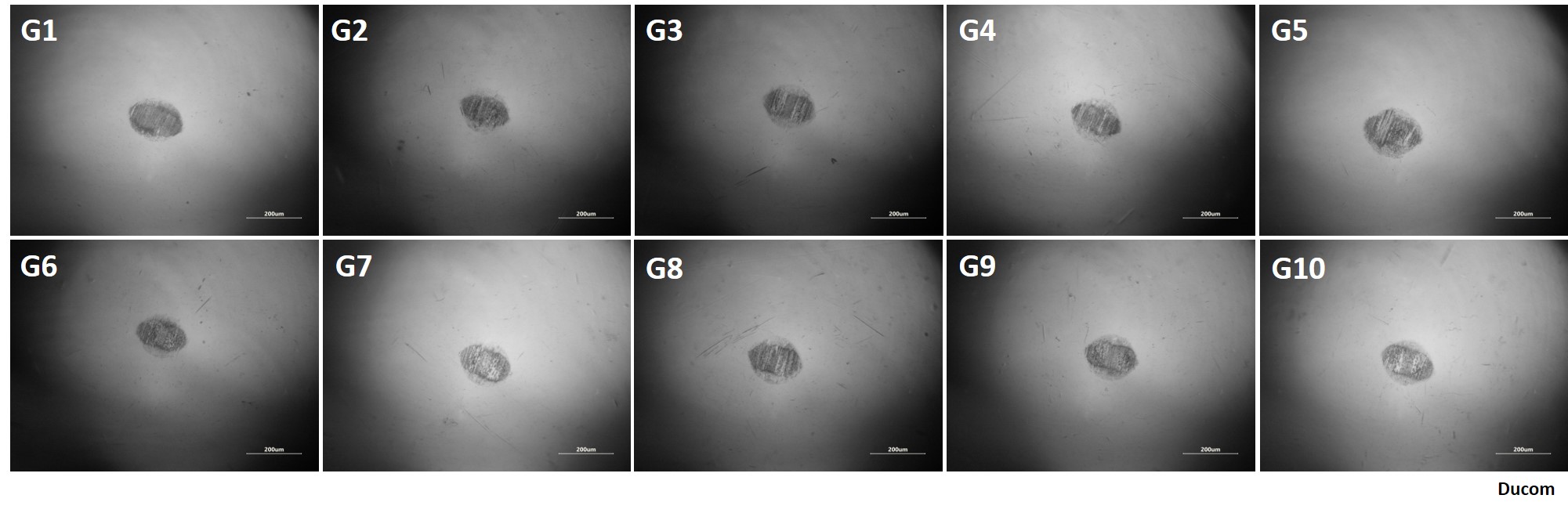

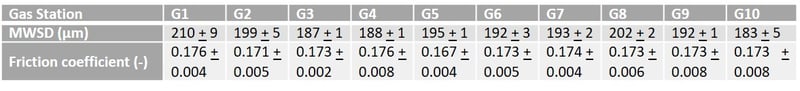

Ball Mean Wear Scar Diameter (MWSD): As shown in Figure 4, all the mean wear scar diameters (MWSD) reported in this research were within the highest MWSD limit for diesel fuel supplied in Netherlands However, the diesel fuel from gas station - G1 showed the highest MWSD value (i.e. 210 + 9 µm) and the standard deviation was significantly higher compared to the other diesels. The diesel G10 showed the lowest MWSD value (183 + 5 µm), followed by the diesel G3 and G4 (187 + 1 and 188 + 1, respectively). Please refer to Figure S3 for the wear scar images on the balls.

Figure 4. Ball mean wear scar diameter (MWSD) values of all the diesel fuels tested using Ducom HFRR. All the diesel fuels are in compliance with the EN 590 /EU VI limits of acceptance i.e. MWSD < 234 µm.

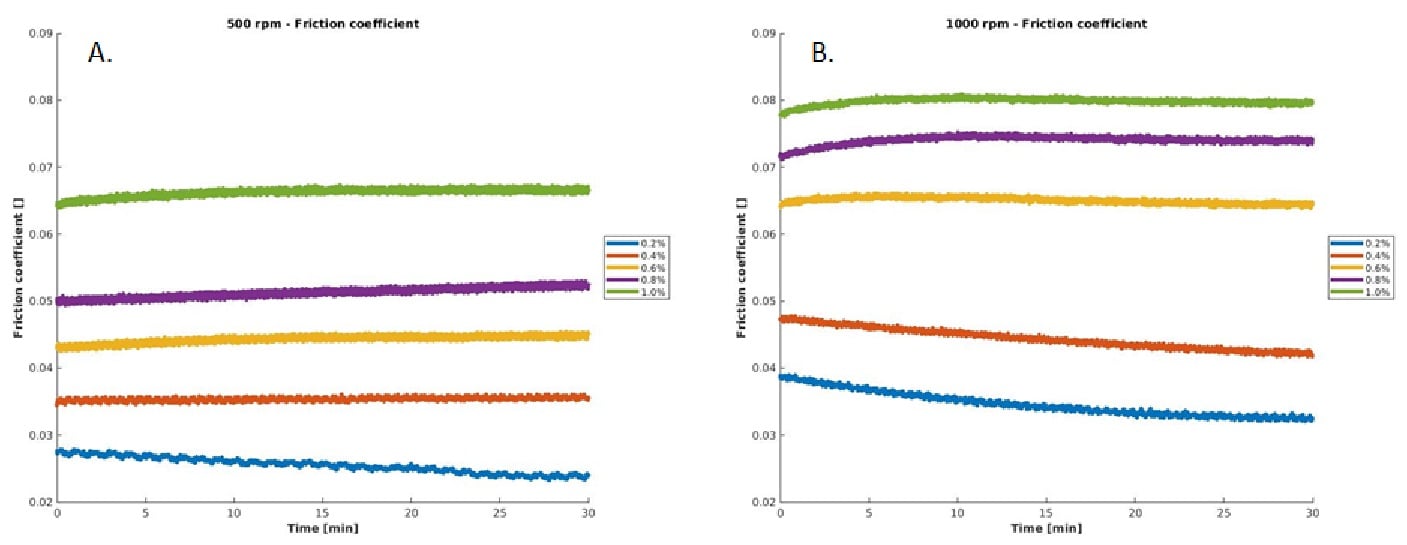

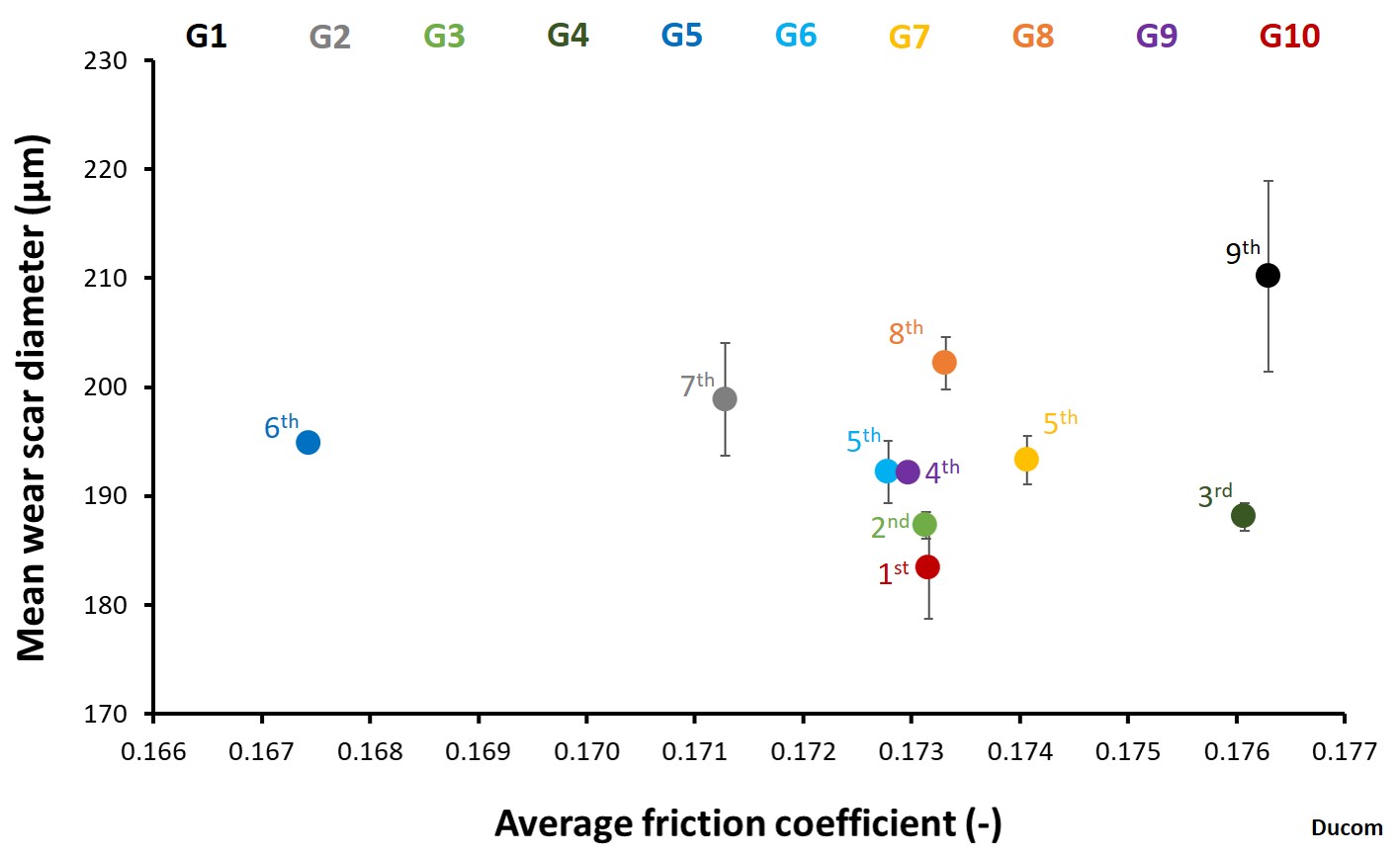

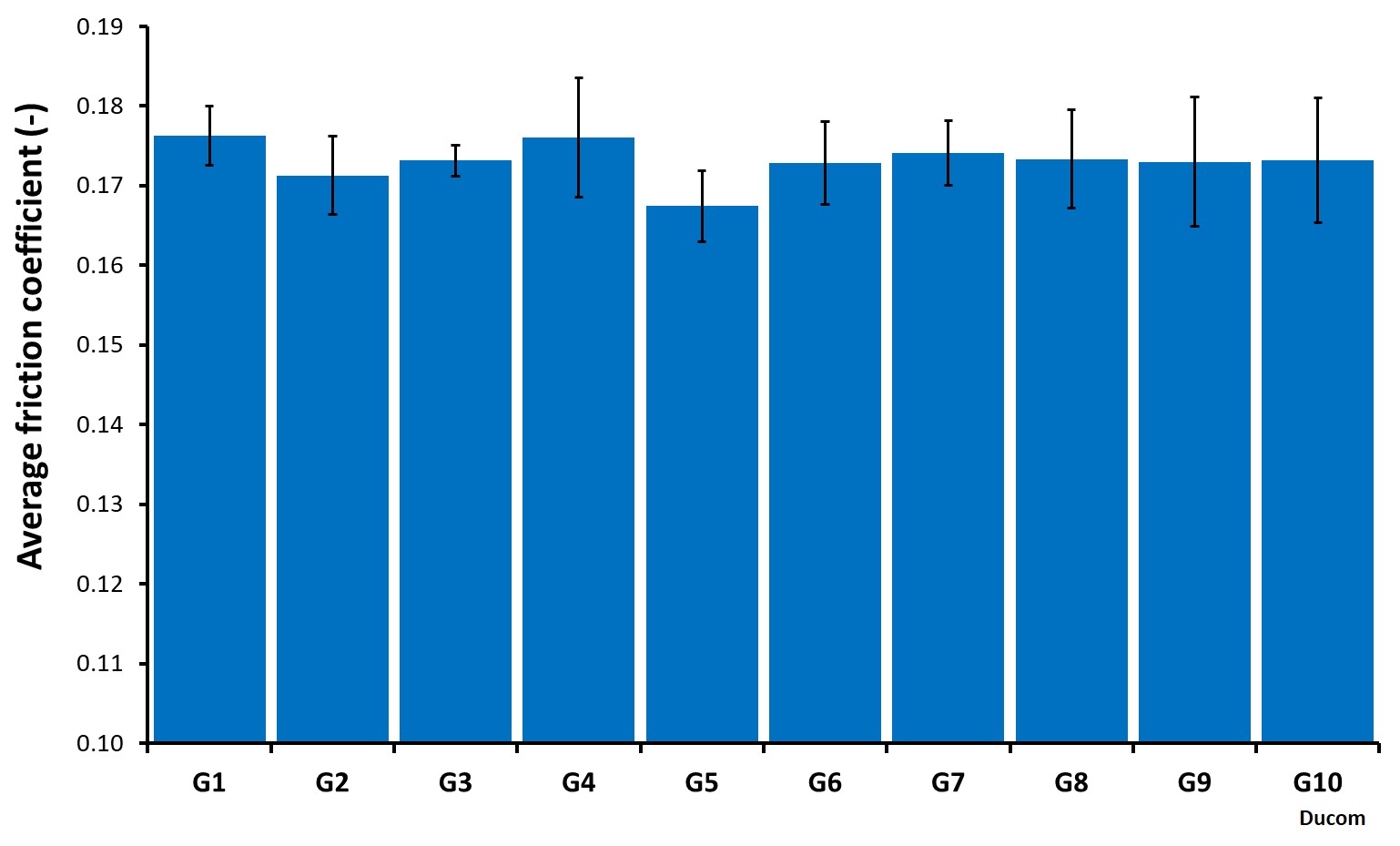

Coefficient of Friction: As shown in Figure 5, the average coefficient of friction was not significantly different for diesel fuels Overall, the diesel fuel G1 and G5 showed the highest and lowest friction coefficient (0.176 + 0.004 and 0.167 + 0.004, respectively). Friction and wear were not in any relationship as shown in Figure 6.

Figure 5. Evolution of the friction coefficient for all the tested diesel fuels. The standard deviation represents three tests per diesel type.

Figure 6. Friction vs. Wear for different diesel fuels. Gas stations were ranked based on the friction and wear values. Lower friction and wear was considered as the best fuel / gas station i.e. G 10.

Conclusions

This random sampling study indicates that all the gas stations comply with the diesel lubricity limits set by EN590. However, there are variations in diesel lubricity between the gas stations. Use of Ducom HFRR was very successful in finding fine differences in diesel lubricity among different gas stations.

Supplementary Material

Figure S1. HFRR study on Reference Fluid A. (A) Evolution of the friction coefficient for reference fluid A during the tests in Ducom High Frequency Reciprocating Rig. The reference fluid A was used to verify the accuracy and calibration of the HFRR after every five tests of diesel fuel. (B) Mean wear scar diameter values of the tested balls are all in compliance with the limits of acceptance set by the ASTM D6079 (284 to 438 µm). (C) Optical microscopy images of the balls.

Figure S2. (A) Evolution of the friction coefficient recorded during the tests in Ducom high frequency reciprocating rig for the reference fluid B. The reference fluid B was used to verify the accuracy and calibration of the HFRR after every five tests of diesel fuel. (B) Mean wear scar diameter values of the tested balls are all in compliance with the limits of acceptance set by the ASTM D6079 (632 to 738 µm). (C) Optical microscopy images of the balls.

Figure S3. Optical microscopy observations of the balls tested in different diesel fuels. The images are one representative test per type.

Figure S4. Average friction coefficient of the tested diesel fuels. The standard deviation is determined over three tests.

Table S1. Average values of the mean wear scar diameter measured on the balls tested in different diesel fuels.

Contact us for more information. Our experts are just a click away.

USA: +1 (847) 737-1590

India: +91 (80) 4080-5555

Netherlands: +31 (85) 065 74 10