Several components used in transportation and energy are exposed to extreme temperature, for example the blades in gas turbines are exposed to hot gases at T > 1000 deg C. Friction and wear performance of these components determine the service life of the system and safety of the operations. Current research is focused on development of new wear resistant materials to protect these components operating at extreme temperature. However, screening these materials at high temperature pose a significant challenge to tribology and scientific instruments.

The pin/ball on disk tribometer with a furnace heating system is widely used for friction and wear testing of heat resistant alloys and coatings. A standard operation procedure is that the tribometer should be calibrated for its friction and wear measurements at 1000 deg C, before testing the research grade materials. However, there are no such protocols being followed in the labs, as there are no reference materials suggested by ASTM. This has an influence on repeatability and reproducibility. Although this problem is recognized by key opinion leaders within tribology community, there is no investigation on the selection of reference materials yet.

Ducom Pin/Ball on Disk Tribometer (PoD 4.0) with a modular design that enables both rotary and linear reciprocating motion in controlled environment chamber, with temperature reaching up to 1000 deg C. Learn more about PoD 4.0

In this ongoing study at Ducom Applications Lab, the scientists have used Ducom PoD 4.0 to screen reference materials for tribology research at T< 1000 deg C. Sapphire was chosen as a reference material for test ball and either Nickel Chromium alloy (Inconel 725) or Silicon Nitride was chosen as a reference material for a counter body, that is, a rotating disk.

Note: Please contact us if you need more information about the composition of these reference materials.

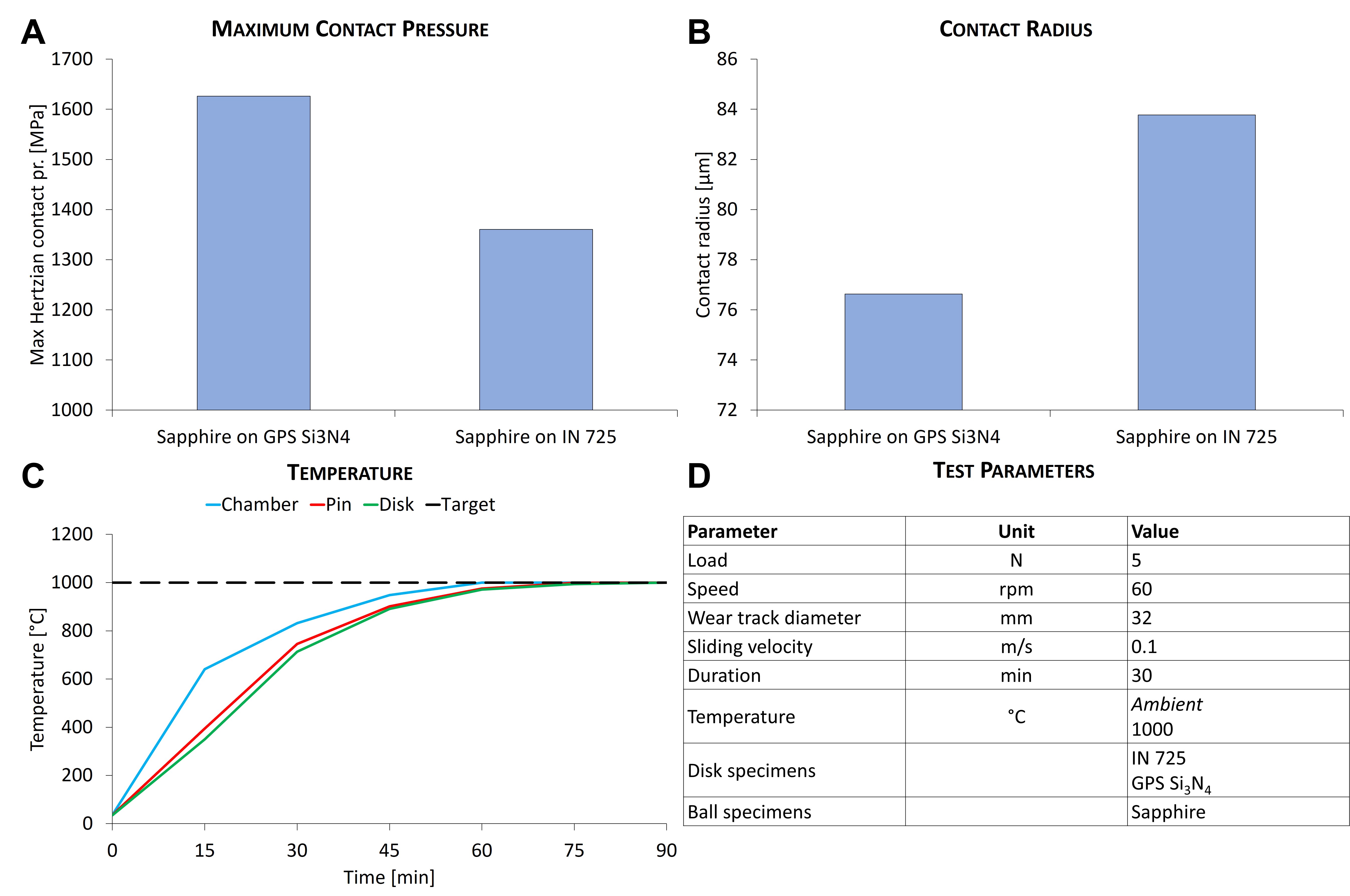

Figure 1. Operating parameters used in Ducom PoD 4.0 Hertzian contact pressure, temperature profile in the furnace and other test parameters as described in the table.

"The tribology challenges that include erosion-corrosion are the bottlenecks in realizing the world's first AUSC plant aimed at reducing carbon emission". Learn more

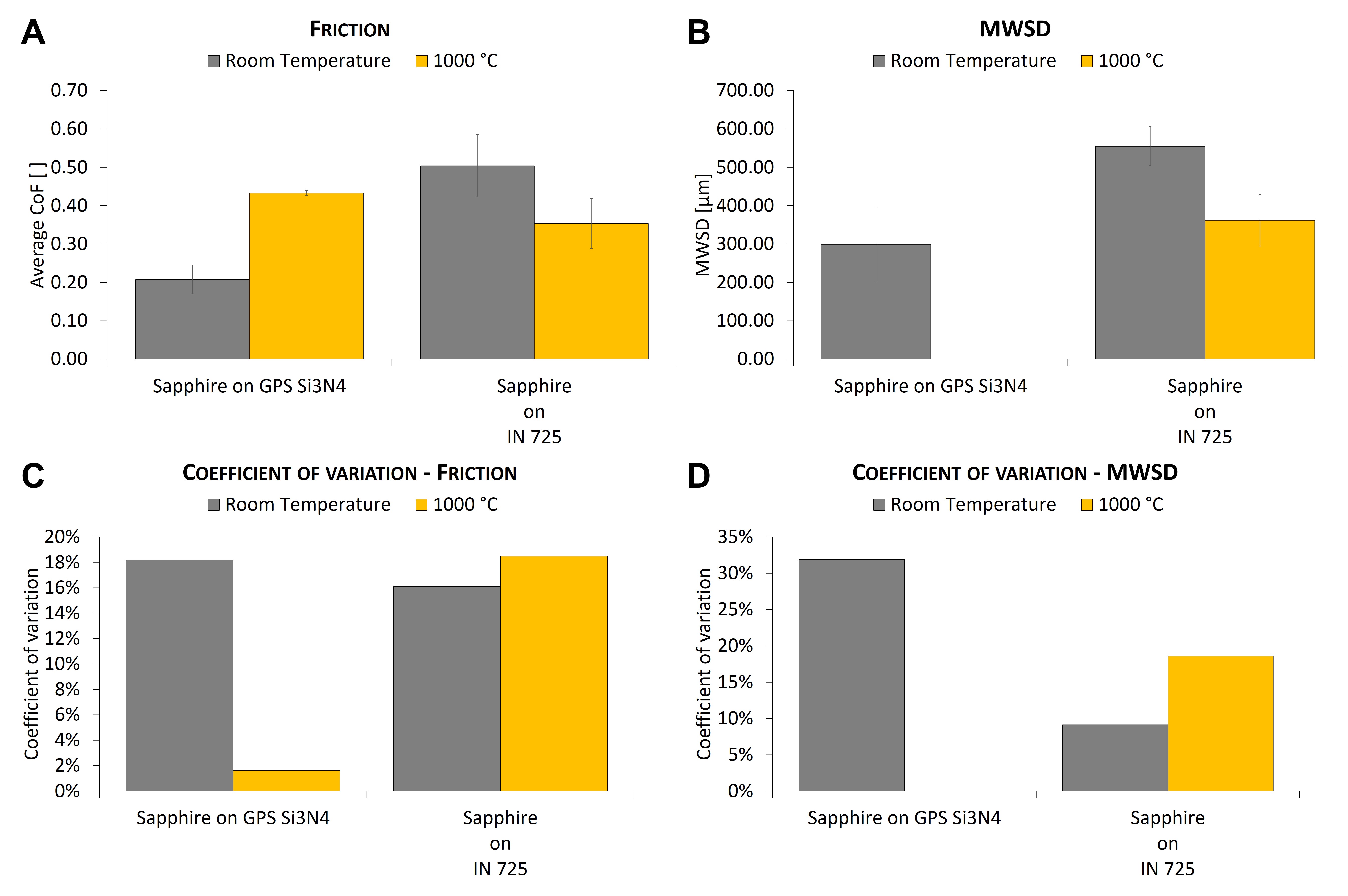

The operating parameters are reported in Figure 1. Each tribo pair was tested at ambient temperature and at 1000 °C. Friction, linear wear and ball mean wear scar diameter (MWSD) were used to differentiate these reference materials. The test were repeated on three different specimens of a given tribo-pair to ensure statistical significance. Coefficient of variation over three test results were used to select the reference materials for calibration.

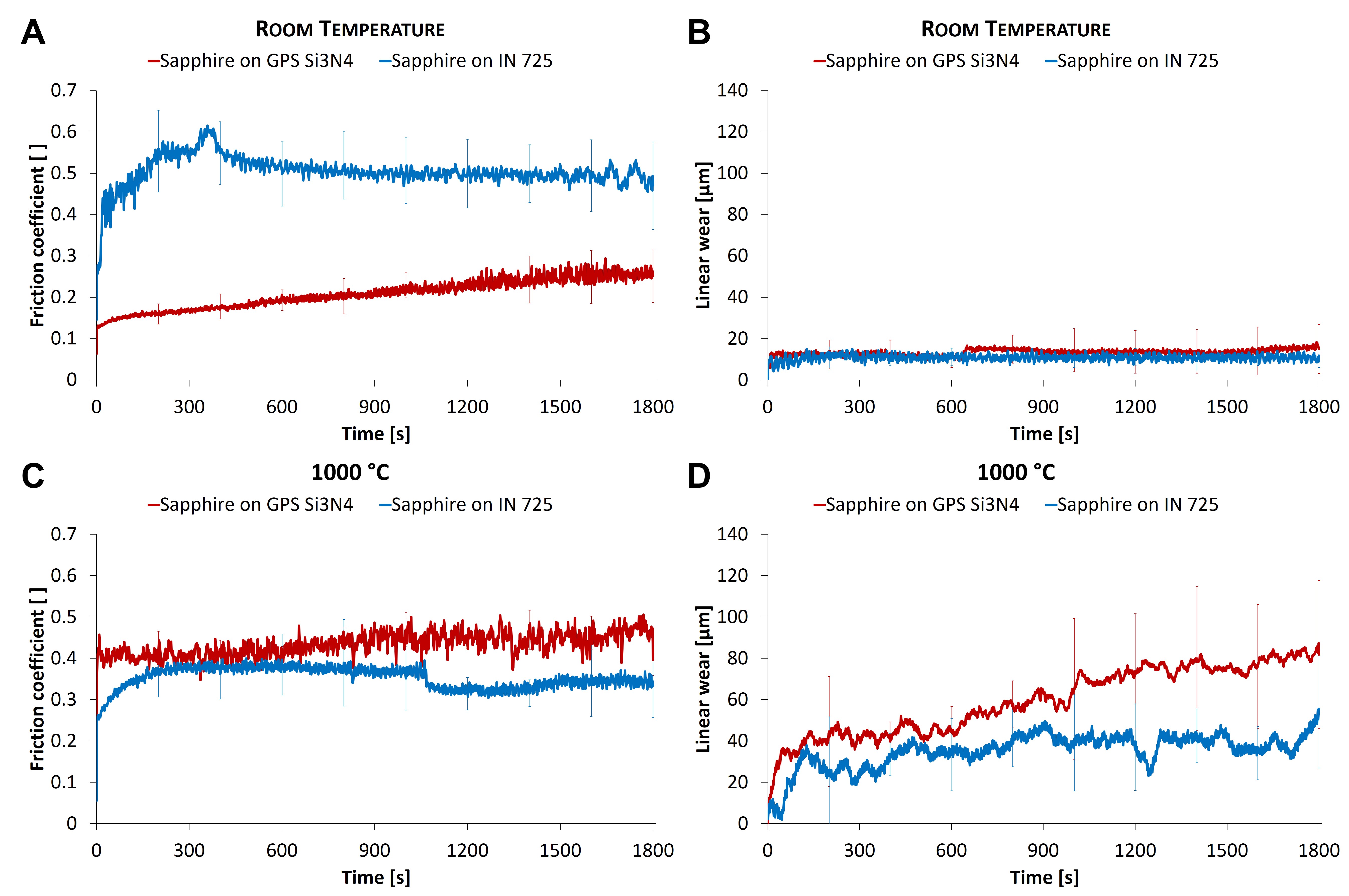

Figure 2. Real time changes in the friction and linear wear at RT and 1000 deg C. Error bars represent the standard deviation over tests on three different specimens.

At 1000 deg C, the friction profile for IN 725 and Silicon Nitride was stable compared with friction profile for the same materials at room temperature (see Figure 2). Post test wear analysis showed visible wear on Sapphire rubbed against IN 725 , whereas there were no visible wear on Sapphire rubbed against Silicon Nitride. As shown in the Figure 3, the coefficient of variation at 1000 deg C was the lowest for Sapphire rubbed against Silicon Nitride. Similarly, the variation over three MWSD test data at 1000 deg C was the lowest for Sapphire rubbed against IN725.

Figure 3. Bar graphs representing the average friction coefficient, mean wear scar diameter (MWSD) on Sapphire balls and their corresponding coefficient of variation.

Figure 3. Bar graphs representing the average friction coefficient, mean wear scar diameter (MWSD) on Sapphire balls and their corresponding coefficient of variation.

This study demonstrates the good repeatability with respect to coefficient of variation for reference materials tested at 1000 deg C. Based on the lowest coefficient of variation, the suggested reference materials for calibrating wear at 1000 deg C is Sapphire on IN 725 and the reference materials for calibration of friction at 1000 deg C is Sapphire on Silicon Nitride.

"Ducom PoD 4.0 was very useful in selection of reference materials for friction and wear test at 1000 deg C."

Contact us for more information. Our experts are just a click away.

USA: +1 (847) 737-1590

India: +91 (80) 4080-5555

Netherlands: +31 (85) 065 74 10