Could you give me a brief overview of tribology testing and its importance in global issues?

Could you give me a brief overview of tribology testing and its importance in global issues?

Any scientific instrument in the lab that can measure friction force or wear of moving parts can be referred to as “Tribology Test Instrument”. A bigger goal of such instruments is to reproduce the friction and wear mechanisms of materials operating in real or ‘field’ conditions. It was in 1927 after the invention of Pin on V block test instrument that a systematic approach to tribology testing was initiated which led to several standardized test methods being developed.

Tribology test instruments are split into two general categories Standard and Customized Instruments. Standard test instruments comply with the instrument design and experimental methods focusing mainly on the repeatability and reproducibility of test results, as prescribed by organizations such as ASTM, ISO, DIN, CEC, IP, etc. The standard test methods are not aimed at reproducing the operating parameters and wear mechanisms experienced during real / field operations. This drawback in standard test instruments is overcome using customised instruments.

Recently, the Volkswagen emission scandal and Johnson and Johnson’s hip replacement recall have shown that there was purposeful cheating on testing protocols or the test results were completely ignored which will cost several billion dollars. Although tribology was not the only reason behind those scandals, it highlights the importance of testing and how it affects us.

Recently, the Volkswagen emission scandal and Johnson and Johnson’s hip replacement recall have shown that there was purposeful cheating on testing protocols or the test results were completely ignored which will cost several billion dollars. Although tribology was not the only reason behind those scandals, it highlights the importance of testing and how it affects us.

I believe that tribology testing will ensure product compliance within industry standards that protects our environment and improves overall safety. There are three key global issues: climate change, renewable energy and healthy ageing, that can be addressed by enabling the best research practices through technologically superior test instruments.

How does tribology testing affect climate change?

Transportation and mining are two examples of human activities that generate greenhouse gases responsible for climate change. Carbon dioxide, Nitrogen oxide and Sulfur oxide are some of the waste gases produced when cars, trucks, buses are used or when drilling, grinding and digging are undertaken in mining. It is important to note that a significant part of the energy in fuel is lost due to friction, for example 33 % of the total energy from fuel in heavy duty vehicles (trucks and buses) is used to lessen friction between moving parts (source: Kenneth Holmberg, VTT in Finland). Therefore, friction is a villain in this story of “saving planet earth”. However, tribology research has shown that friction can be controlled using cutting edge technology from the field of materials science. As a result of this research into friction a substantial net reduction in carbon dioxide emission is possible as seen in figure 1 which shows that friction and wear are directly linked to climate change.

Figure 1. Friction and wear of materials are related to carbon emission.

Figure 1. Friction and wear of materials are related to carbon emission.

The role of tribology testing is to screen for friction reducing materials and identify the most suitable candidate material in transportation and mining the results of which can be seen in table 1.

Table 1. Ducom tribology test instruments and relevant standards used to investigate materials that reduce friction and wear.

How does tribology testing affect renewable energy?

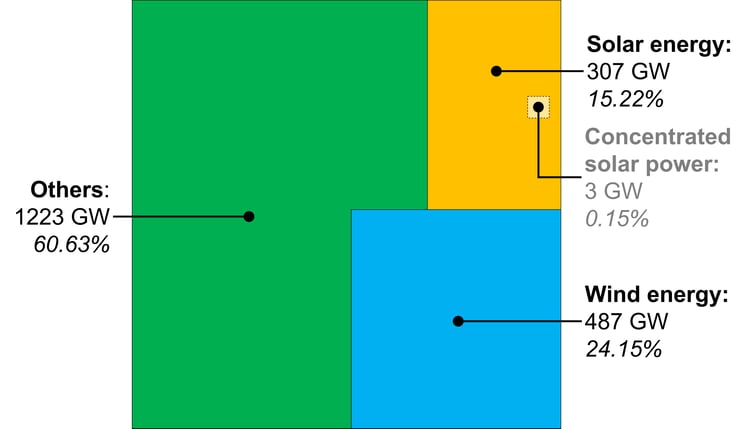

Approximately, 20 % of global energy demand is met by renewable energy. As shown in figure 2, total renewable energy production in 2016 was 2017 GW, where the share of solar photovoltaics (PV) and wind power was 303 GW and 487 GW, respectively. Efficiency of solar PV and wind turbines largely depends on their ability to resist weathering from to rain and sand storms.

Figure 2. Different source of renewable energy generated in 2016.

Figure 2. Different source of renewable energy generated in 2016.

Solar panels installed in desert regions are exposed to sand particles. These particles impact damages the glass panels protecting the photovoltaics (PV’s) this process is called solid particle erosion. Erosion of the glass panels leads to diffused reflectance and reduces the light transmission by 36 % (Bouzid et. al., J. Eur. Ceram. Soc., 2000, 20: 481488).

This is a significant blow to solar power because the conversion rate is already low, at 20 %. Several types of erosion resistant coatings are being developed to resist particle impact and improve optical transmission to 100 %. The Ducom Air Jet Erosion Tester is used in the lab to reproduce the solid particle dynamics in deserts and the related erosion mechanisms. This testing method is used to select the protective coatings that can optimize the solar power efficiency.

Similarly, the edges of wind turbine blades can be damaged by the impact of rain droplets this process is called as water droplet erosion. There are small pits and delamination which can occur on the edges of the blades which in turn reduces the aerodynamic efficiency of the wind farm. A study by Sareen et. al., (Wind Energy, 17, 2014) has shown that erosion of turbine blades can lead to a loss in power of up to 392 MWh/y. The Ducom water droplet erosion tester can be used in the lab to mimic the field operating parameters (rain droplet size, droplet velocity, impact angle, rainfall rate, etc.) to test erosion resistant coatings for the protection of turbine blades. The main point to take away from this is that Ducom erosion testers are playing a key role in improving the efficiency of solar and wind power energy production.

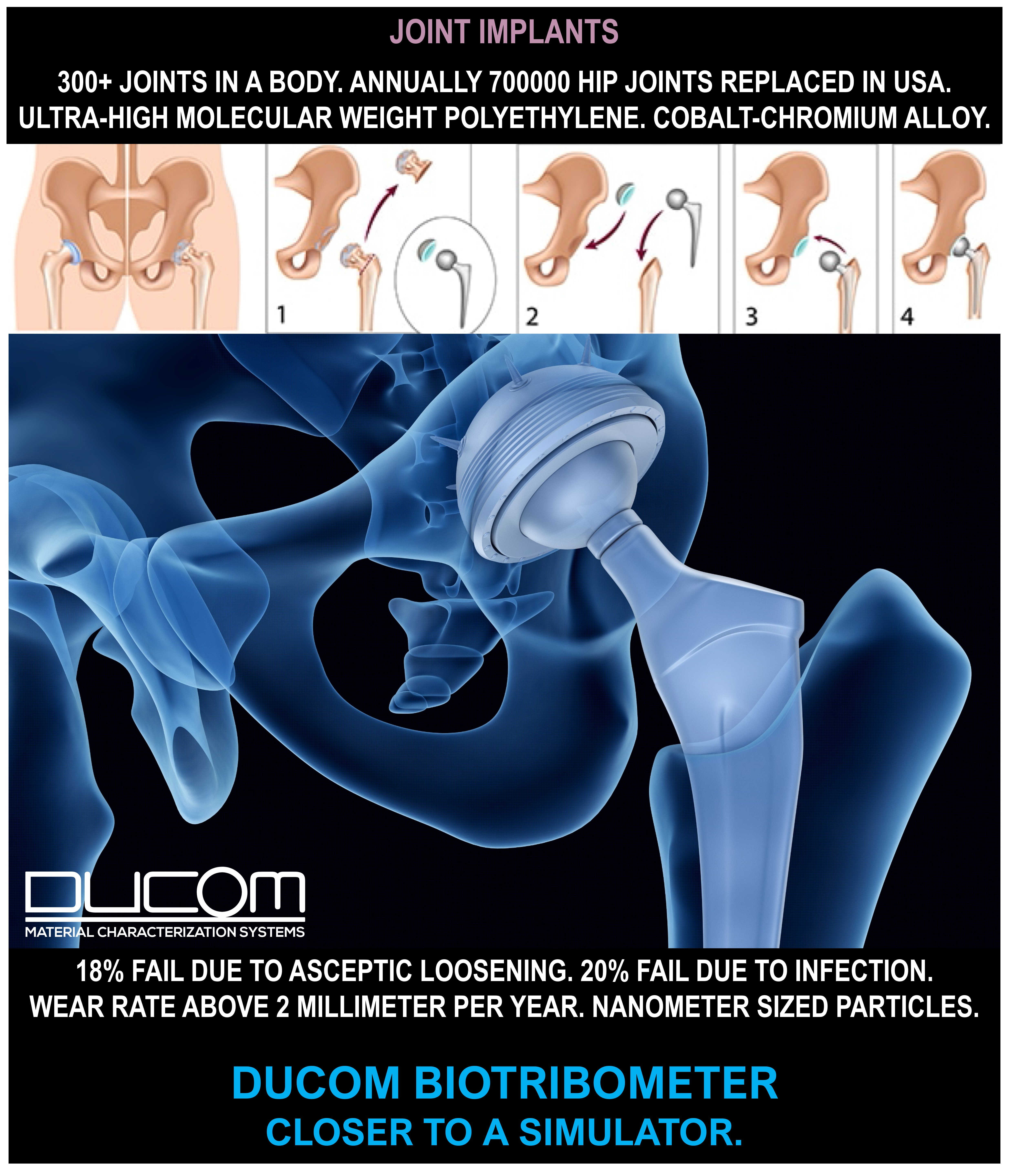

How does tribology testing affect healthy ageing?

On average life expectancy is increasing due to several lifesaving medical innovations however living longer does not necessarily correlate to healthier living. A basic concept of healthy ageing is to provide better quality of life during the ageing process. Some of the

factors affecting the quality of life are from biomaterial associated infections; Sjogren’s syndrome – dryness of the mouth, eyes and joints as well as the quality of consumer care products. In these cases, friction and wear play an important role, the wear of biomaterials is a major issue in causing implant failure. An inability to sustain natural lubrication in the mouth and eyes leads to a poor social life amongst those suffering from Sjogren’s syndrome, skin irritation after using consumer care products is also related to high friction and limited sensory perception.

In this the responsibility of tribology testing is twofold; the need to simulate the physiological operating conditions in the lab as well as providing a high level of repeatability and reproducibility of the test results. These test instruments are used in screening for and selecting wear resistant biomaterials, ultralow friction physiological

lubricants and skin contact materials which in turn can improve sensory perception.

We are constantly engaged in discussions with key opinion leaders within biomaterials research, these discussions have helped us to develop two tribology testing instruments: the Ducom BioTribometer and the Ducom UniTest. The Ducom BioTribometer (in compliance with ASTM test standards related to dentistry and orthopedics) is used in screening of low wear biomaterials like UHMWPE’s, TiAV, TiNbN coating, DLC coating, ZrO , Al O , Stellite’s, etc. The Ducom Unitest with MicroForce head is an ultralow force test instrument that can simulate the contact pressure between the eyelid and cornea (~ 10 kPa) and it is used to develop better contact lenses and synthetic physiological lubricants.

How does DUCOM stand out from other companies in your field?

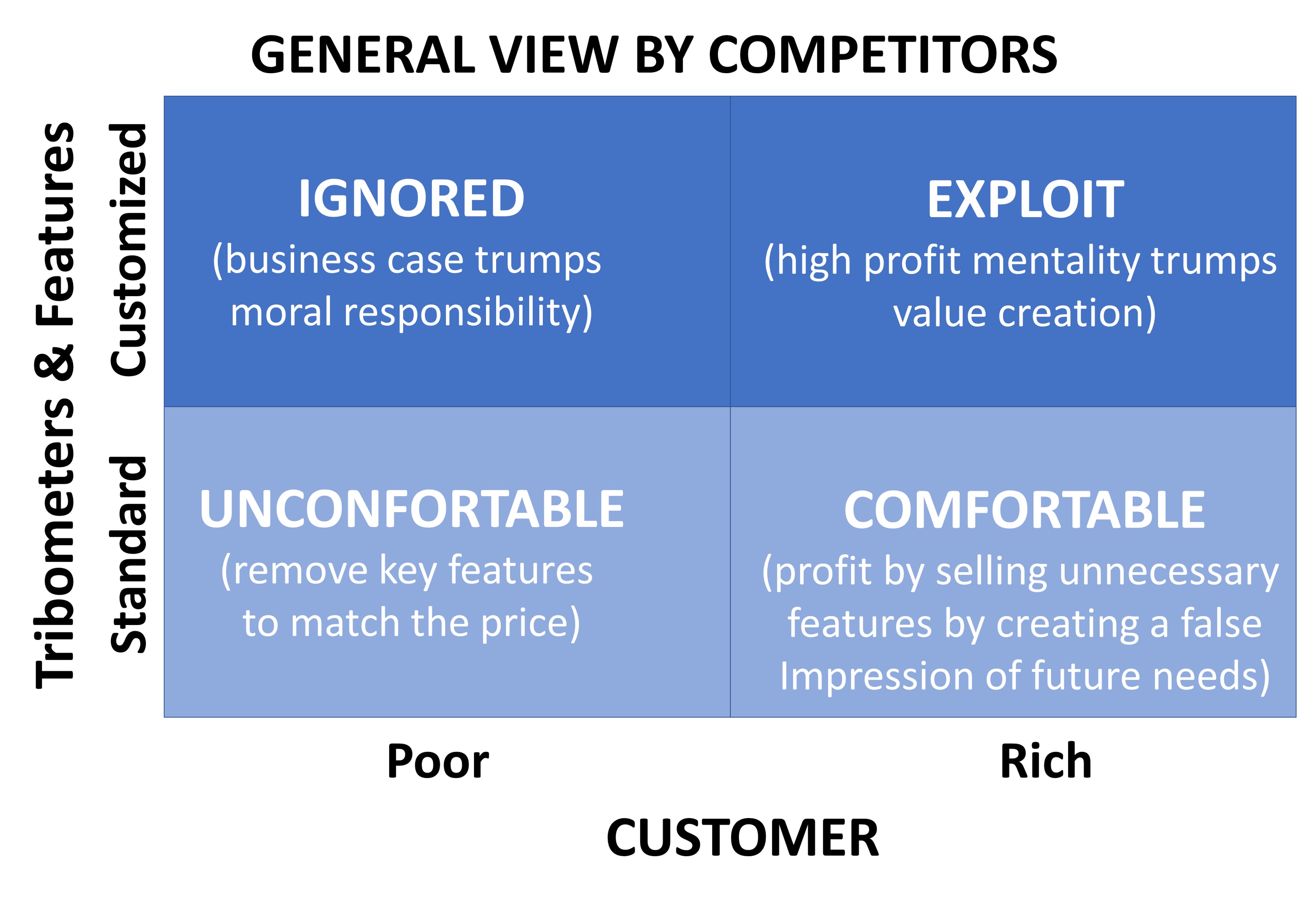

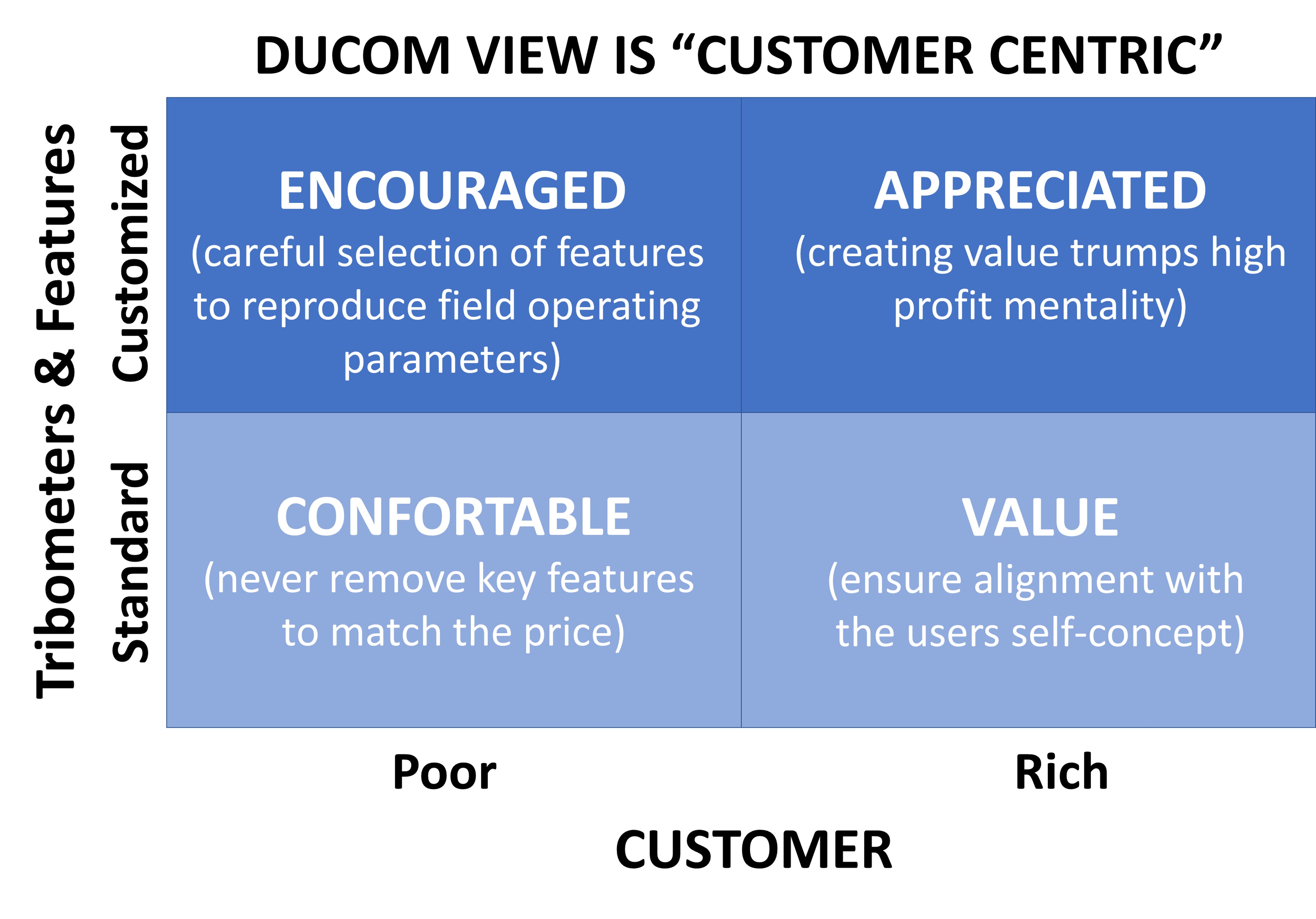

Ducom Instruments was founded in 1978 by Mr. Narendra Mohan Dube. We have a history of 40 years in Tribology. Today we have more than 1500 installations in 25 countries and we serve our customers and sales partners worldwide through our global centers in Netherlands, USA, India and Malaysia. We attribute this success to Mr. Dube’s philosophy that explicitly states that a sale is only a means to an end and the end is when it creates value to our customer. We continue to follow his philosophy that has allowed us

to dominate with a “customer centric” approach to the market. Our approach is very different to that of our competitors in the same business seen and our customers have long term benefits from our approach.

Our approach to product creation is that of “Not All in One but One for All” – a single source with different tribology testing instruments that address wide range of problems from erosion of engine blades at 1200 °C to friction behavior of contact lenses at 10 kPa. This is because we believe an “All in One” approach only partially cover features of multiple tribology testing instruments thus producing less than satisfactory results and increases opportunity cost and lower research throughput.

Our approach to product creation is that of “Not All in One but One for All” – a single source with different tribology testing instruments that address wide range of problems from erosion of engine blades at 1200 °C to friction behavior of contact lenses at 10 kPa. This is because we believe an “All in One” approach only partially cover features of multiple tribology testing instruments thus producing less than satisfactory results and increases opportunity cost and lower research throughput.

Furthermore, our post sale service is unique, we offer a comprehensive support which increases the value of the customer’s tribology testing instrument. Being an SME, we can afford to spend “quality resources” to ensure customer wellbeing, we would rather chase the customer satisfaction than chasing profits that are ephemeral.

Furthermore, our post sale service is unique, we offer a comprehensive support which increases the value of the customer’s tribology testing instrument. Being an SME, we can afford to spend “quality resources” to ensure customer wellbeing, we would rather chase the customer satisfaction than chasing profits that are ephemeral.

What are the plans for moving forward with DUCOM?

We believe that tribology testing instruments should have minimum human interaction to enable high research throughput. In this regard, the Ducom high temperature tribometer in Lulea University is a good example. This test instrument is programmed to automatically mount the sample, heat up to 1000 ̊C and run 100 friction and wear tests according to the preset operating parameters. Another such example is our new Ducom Four Ball Tester – FBT3 allows users to conduct 5 to 8 wear preventive tests compared to a conventional four ball tester that only allows 2 to 4 wear preventive tests per day.

Apart from improving the number of measurements we are also focused on technologies that can assist scientists in the understanding and analysis of the data that has been produced, our motto is “Measure, Understand and Analyze”.

We are trying our best to execute all the above without significantly changing the price structure. We have put significant resources into cost engineering to make it affordable to all of our potential customers in industry and research.

These Stories on wear

USA: +1 (847) 737-1590

India: +91 (80) 4080-5555

Netherlands: +31 (85) 065 74 10