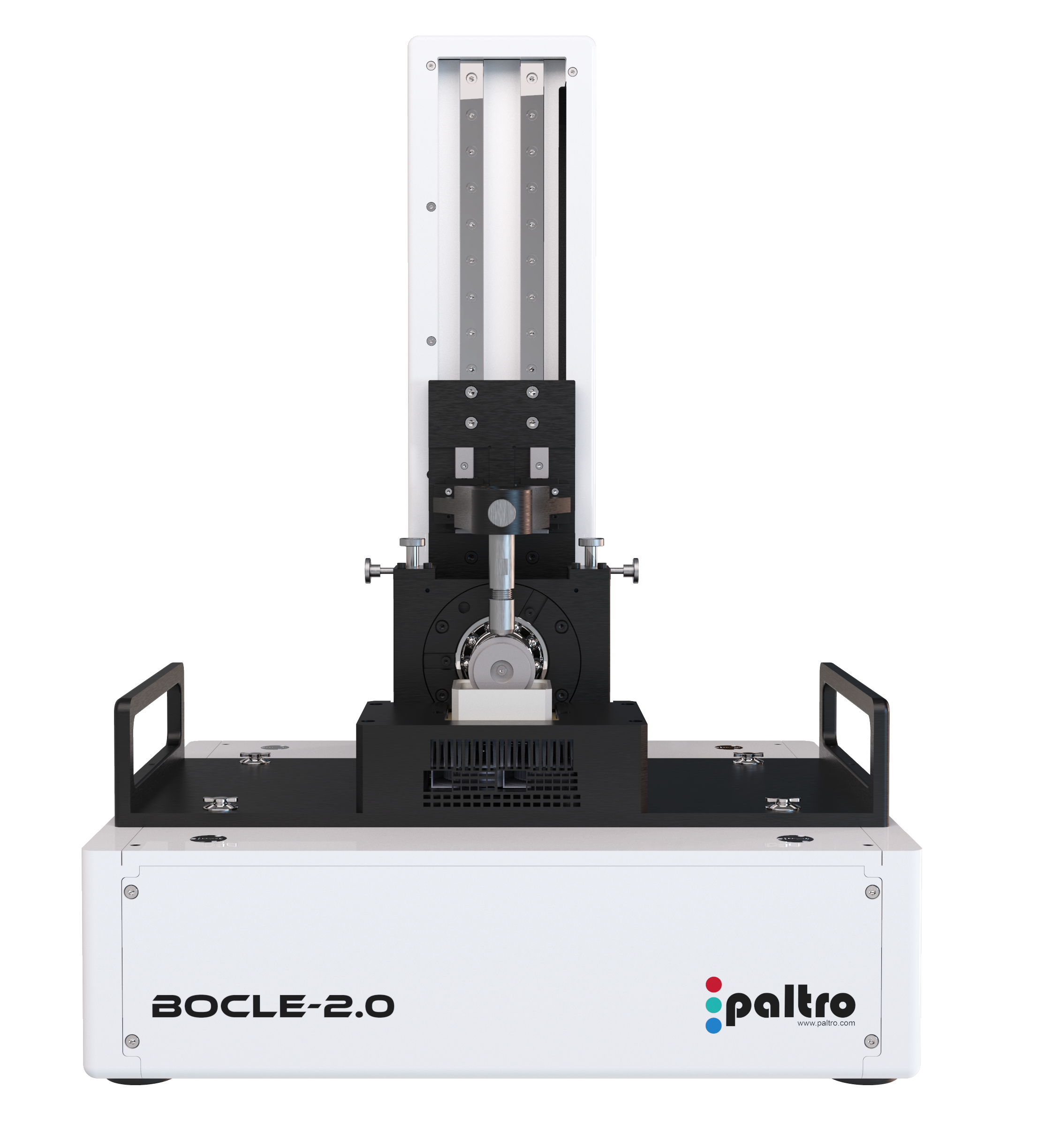

Introducing the

BOCLE 2.0, a fully automated Ball-on-Cylinder Lubricity Evaluator specifically designed for Aviation Turbine Fuels (ATF). The BOCLE 2.0 offers efficiency, reliability, and ease of use for quality control laboratories focused on jet fuel lubricity assessment.

Paltro's BOCLE 2.0

Test Method

The BOCLE test method, standardized under ASTM D5001, is crucial for evaluating the lubricating properties of aviation turbine fuels. This test protocol employs a ball-on-cylinder contact geometry, where a non-rotating steel ball is pressed with a defined load against the outer surface of a rotating cylindrical steel ring. The ring is partially immersed in the fuel sample being tested.

A typical 45-minute test cycle includes a 15-minute pre-treatment phase followed by a 30-minute actual test. Upon completion, the wear scar formed on the steel ball is measured under a microscope. The mean wear scar diameter serves as an indicator of the fuel's lubricity – with smaller wear scar dimensions indicating superior lubricating properties. The test protocol defines the normal load (1000 g), rotational speed (240 rpm), fluid volume (50 ml), fluid temperature (25 °C), and conditioned air properties (10 % RH at 25 °C), along with precise flow rates for the pre-treatment and test phases.

Details of Paltro's BOCLE 2.0 test area

Paltro's BOCLE 2.0 is engineered to execute this standardized test procedure with unparalleled automation. The system features a unique hybrid automated loading mechanism, a first in the market, which automatically applies the calibrated weight after the pre-treatment phase. This soft, motorized loading system eliminates any impact or jerk, removing a significant source of user-induced variability. Furthermore, a sophisticated conditioned air unit with programmed logic autonomously controls air flow rates and seamlessly switches between pre-treatment and test phases. Integrated sensors continuously monitor and log critical test parameters like fuel temperature and relative humidity, assigning a unique ID to each test for complete traceability and compliance. The innovative slide-n-fit spacers on the lower ring allow for lateral offset after each test, enabling up to ten tests per ring and maximizing consumables utilization. The intuitive user interface simplifies the entire testing process, allowing users to initiate a complete test sequence with a single click. Additionally, built-in water level and pressure sensors provide timely alerts for routine maintenance. Importantly, Paltro serves as a single-source supplier for the instrument, test rings, balls, and accessories, ensuring stringent quality control across all components.

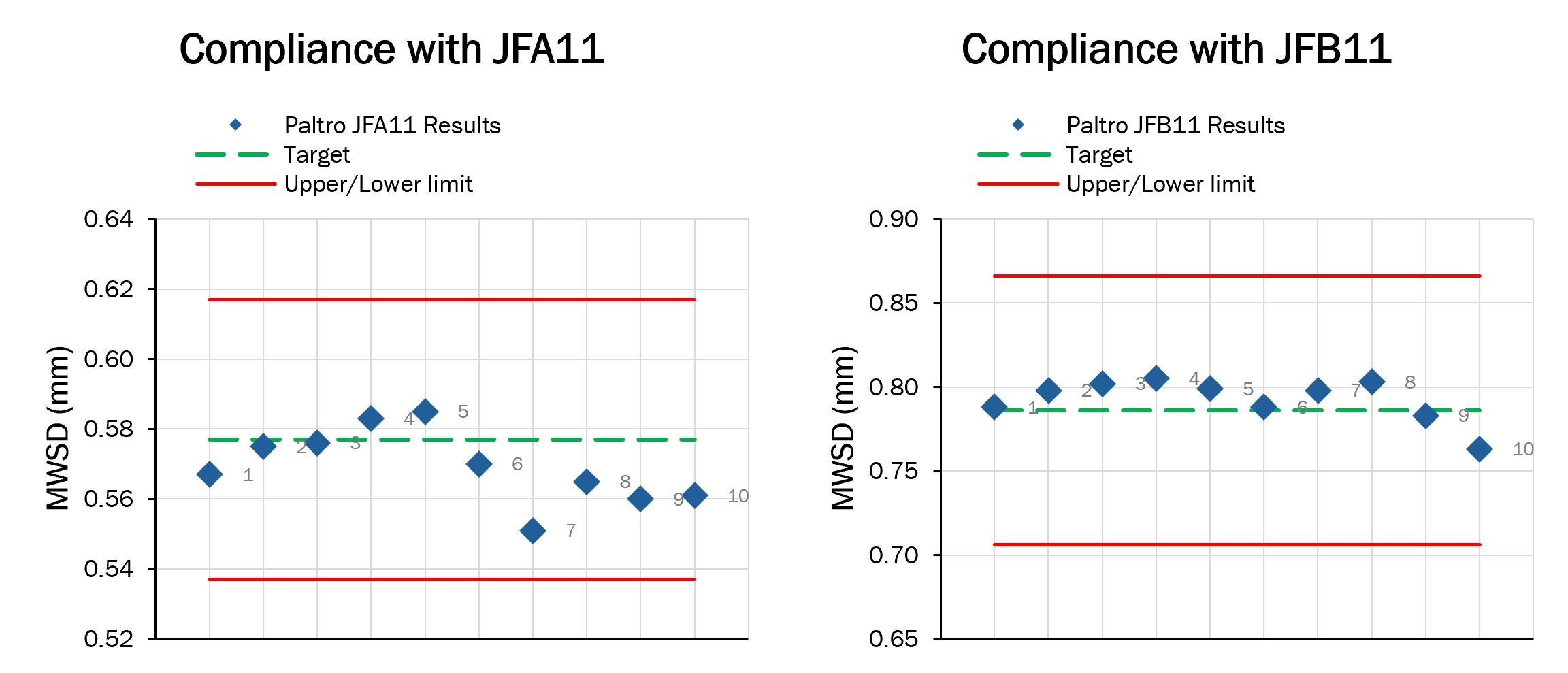

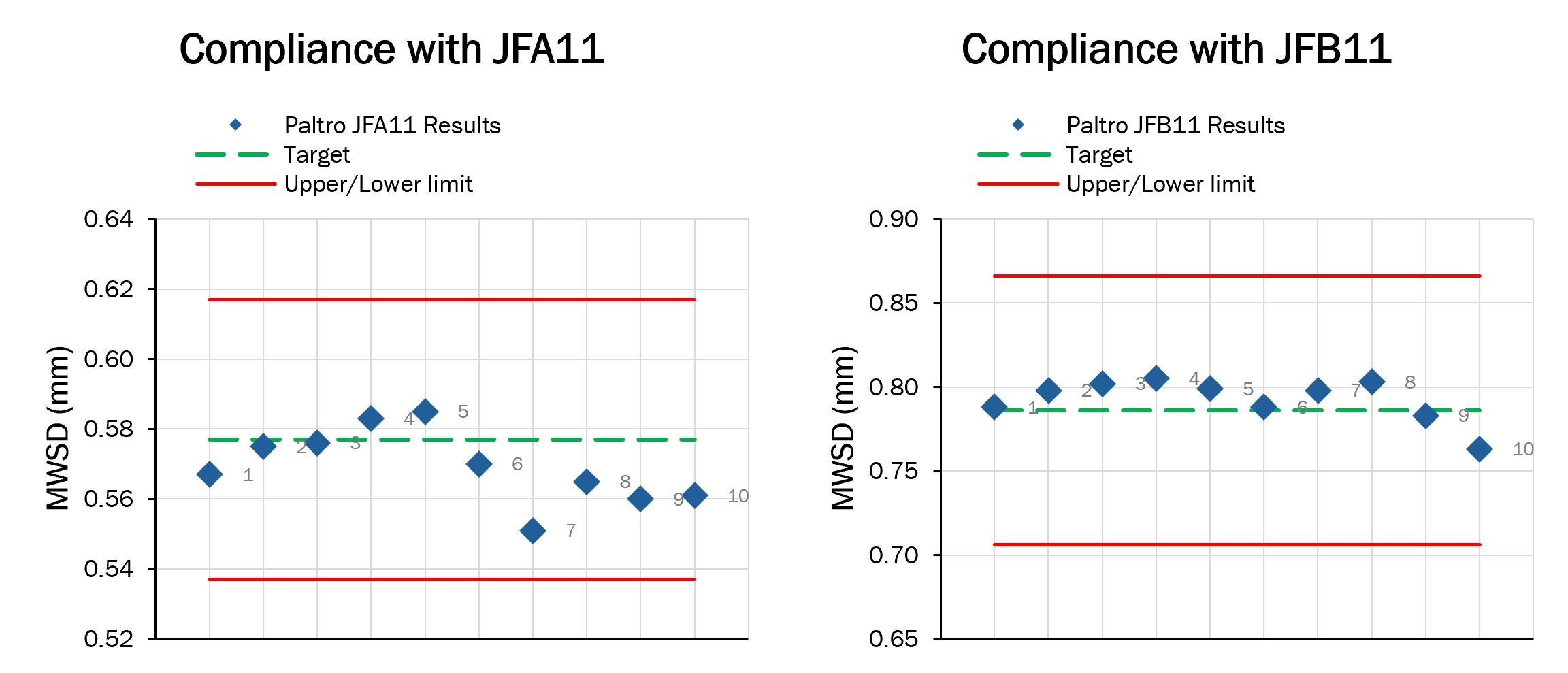

Mean Wear Scar Diameter obtained on Paltro's BOCLE 2.0 for 10 tests run on reference fluid JFA11 (left) and JFB11 (right) against their respective target and acceptance limits

The core objective for users of BOCLE is to ensure that tested fuel samples meet the lubricity requirements defined by the JFA11 and JFB11 specifications. Paltro's BOCLE 2.0 is rigorously tested, and control tests with reference fluids are conducted to ensure that the mean wear scar diameter values fall well within the acceptability range. This consistent performance is confirms the instrument's accuracy and reliability in providing crucial quality control data.

Summary of the results obtained on Paltro's BOCLE 2.0 on reference fluid tests. Paltro's BOCLE shows a better precision on the results on both JFA11 and JFB11

Paltro's BOCLE 2.0 offers significant unique advancements, such as a fully automated loading system and automatic control of the entire ASTM D5001 test sequence (including flow rate and conditioned air), an automated workflow for microscopy, analysis, and report generation, and the advantage of being a single source supplier for both test rings and equipment.

This automated BOCLE 2.0 enhances lab productivity and provides reliable, traceable fuel lubricity data, enabling confident and rapid quality control decisions.